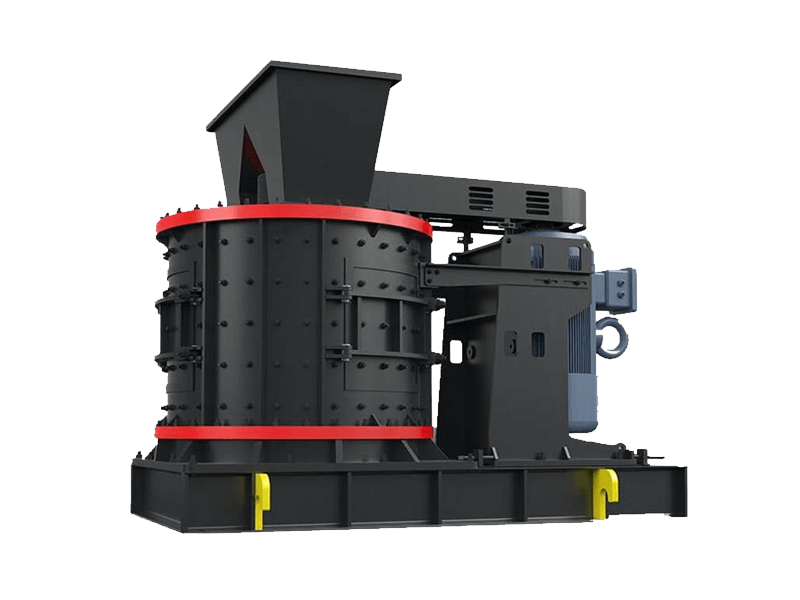

The compound crusher is also called a "vertical compound crusher" because the body of the crushing equipment is upright. The so-called "compound" is because it combines two different crushing forms of impact crusher and hammer crusher into one. One operation cycle can achieve coarse, medium, and fine crushing. It has outstanding advantages such as one-time molding, large crushing ratio, energy saving, good sealing, and less dust. It fully simplifies the crushing process, improves efficiency, and reduces investment costs. The vertical crusher is an optimized design, mature technology, and widely used fine crushing equipment.

High crushing efficiency and low crushing cost

It has the advantages of impact crusher and hammer crusher. One device plays the role of two devices, which significantly simplifies the process and reduces investment costs.

One time can achieve coarse crushing, medium crushing and fine crushing.

When used in ore dressing, limestone and cement plants, it can significantly reduce the feed particle size of the subsequent ball mill, thereby increasing the output of the entire production line and reducing the energy consumption of the entire set of equipment.

Good sealing and no dust pollution

The crushing device has good sealing and no dust pollution.

Can be used for crushing materials with high water content

The discharge particle size can be easily adjusted and has strong adaptability. According to the data of the Kunming Crusher Technical Expert Group, materials with a water content of 8%-15% can enter the compound crusher for normal crushing.

The material falls vertically from the upper part of the machine into the high-speed rotating impeller. Under the action of high-speed centrifugal force, it collides and crushes with the other part of the material that is diverted around the impeller in an umbrella-shaped form. After colliding with each other, the materials will form a vortex between the impeller and the casing, and then rub and crush each other multiple times, and then be discharged directly from the bottom, forming a closed-loop multiple circulation, and the screening equipment controls the required finished product particle size.

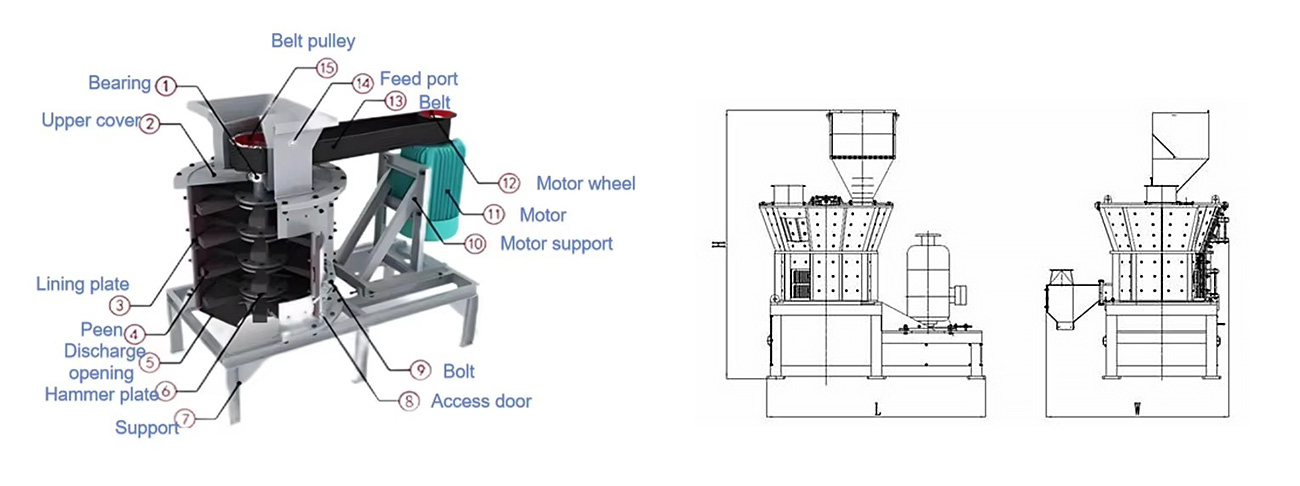

The compound crusher consists of a transmission device, a body, a feeder and a support. The main body parts can be divided into a cover, a casing, a hammer head, a hammer disc, a liner, a center shaft, etc. The hammer head is fixed on the hammer disc in a radial layout, and the hammer disc is fixed on the center shaft in a stacked layer at a fixed interval. For the specific structural layout, please refer to the following vertical compound crusher internal structure profile:

The processing capacity of the vertical compound crusher equipment is affected by many factors, such as: the physical properties, shape, particle size composition, water content, workbench conditions, etc. of the crushed raw materials. The processing capacity listed in the above table is based on the crushing of dry and medium-hard rock as an example, and the bulk density is based on 1.6t/m3.

| Specifications | Drum diameter | Feed size (mm) | Discharge size (mm) | Spindle speed (r/min) | Production capacity* (t/h) | Motor power (kW) | Overall dimensions (mm) |

| PCL7504 | Φ800 | ≤50 | ≤10 | 720 | 12-30 | 37 | 2500×1320×1453 |

| PCL1000-3 | Φ1000 | ≤60 | ≤10 | 500 | 20-30 | 55 | 2790×1550×1545 |

| PCL1250-3 | Φ1250 | ≤70 | ≤10 | 420 | 30-50 | 90 | 3205×1750×1670 |

| PCL1500-3 | Φ1500 | ≤100 | ≤15 | 420 | 50-100 | 132 | 3500×1960×1850 |

| PCL1750-3 | Φ1750 | ≤120 | ≤20 | 350 | 70-150 | 160 | 3925×2200×2350 |

Applicable materials: river pebbles, granite, basalt, iron ore, limestone, calcite, quartz, abrasives, refractory materials, concrete aggregates, etc.

Application areas: Provide high-quality sand and gravel aggregates for highways/railways, municipal engineering, hydropower dam construction, port terminals, concrete mixing plants, dry-mix mortar production lines, etc.

Thirty years of dedication have allowed us to accumulate extensive production and service experience, enabling us to solve various challenges in powder processing for our numerous clients.

Innovation is the lifeblood of our company's development. To date, we have obtained over 40 domestic and international patents, with many of our products holding multiple patents.

We specialize in undertaking the design and production of fine powder processing production lines, offering a one-stop service from crushing, screening, conveying, feeding, mixing to packaging.

Upon receipt of the products, detailed English user manuals are provided. For relatively complex installations or product usage, video installation guidance is available. For large-scale technical projects, we can dispatch professional technical personnel for on-site installation guidance.

Please fill in the informationWe provide you with personalized solutions

Please fill in the informationWe provide you with personalized solutionsIf you do not know how to select, please call us or leave a message online. We will serve you wholeheartedly!