As a general-purpose equipment for continuous conveying, belt conveyor is widely used in industrial production. It can transport bulk and granular materials, as well as packaged items such as bagged cement. It is a common conveying equipment. It has the advantages of high efficiency, long transportation distance, low power consumption, simple structure, stable and reliable operation, convenient operation, and low noise pollution. It is usually used in cement plants for mining, crushing, packaging, feeding, metering and stacking.

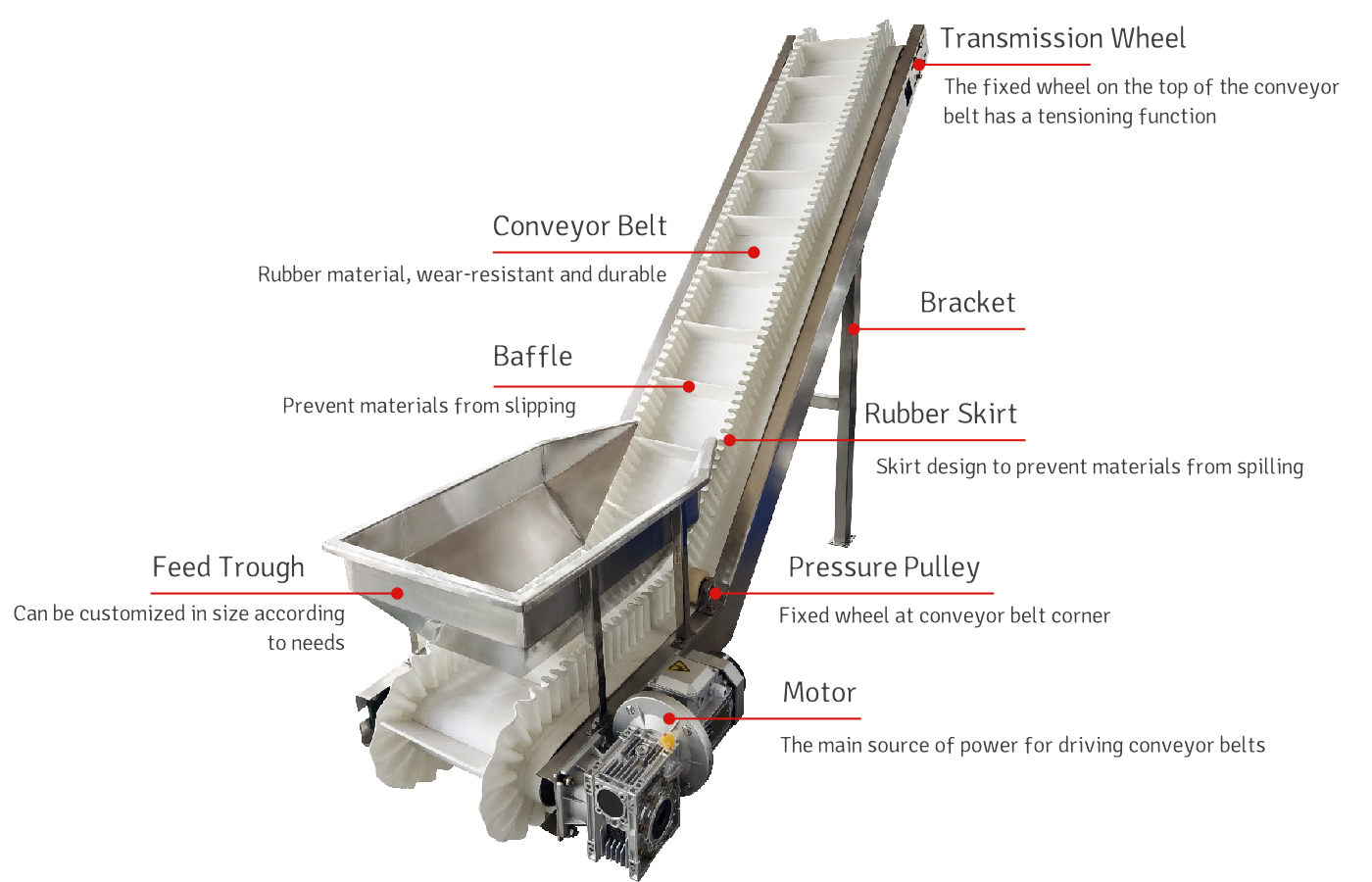

Various structural forms, including trough belt conveyor, flat belt conveyor, climbing belt conveyor, tilting belt conveyor, turning belt conveyor and other forms. Push plates, side baffles, skirts and other accessories can be added to the conveyor belt to meet various process requirements.

The belt conveyor can convey a wide variety of materials, including various bulk materials, various cartons, packaging bags and other small-weight goods, and has a wide range of uses.

Specifications: Standard conveyor belt widths are 500mm, 650mm, 800mm, 1000mm, 1200mm, etc., and other special specifications can also be used according to customer needs. z.m..j..t.0.5.9. The standard turning inner radius of the turning belt conveyor is R185mm, R600mm, R900mm, R1200mm, etc., and other special specifications can also be used according to customer needs.

The structure is diverse, including trough belt conveyor, flat belt conveyor, climbing belt conveyor, tilting belt conveyor, turning belt conveyor and other forms. Push plates, side baffles, skirts and other accessories can be added to the conveyor belt to meet various process requirements.

The belt conveyor has a simple structure, easy maintenance, low energy consumption and low cost of use.

The special food-grade conveyor belt can meet the requirements of food, pharmaceutical, daily chemical and other industries.

The conveying is smooth, there is no relative movement between the material and the conveyor belt, which can avoid damage to the conveyed material.

The conveyor belt is made of rubber, canvas, PVC, PU and other materials. In addition to being used for the conveying of ordinary materials, it can also meet the conveying of materials with special requirements such as oil resistance, corrosion resistance and anti-static.

Compared with other belt conveyors, it has less noise and is suitable for occasions where the working environment requires a relatively quiet environment.

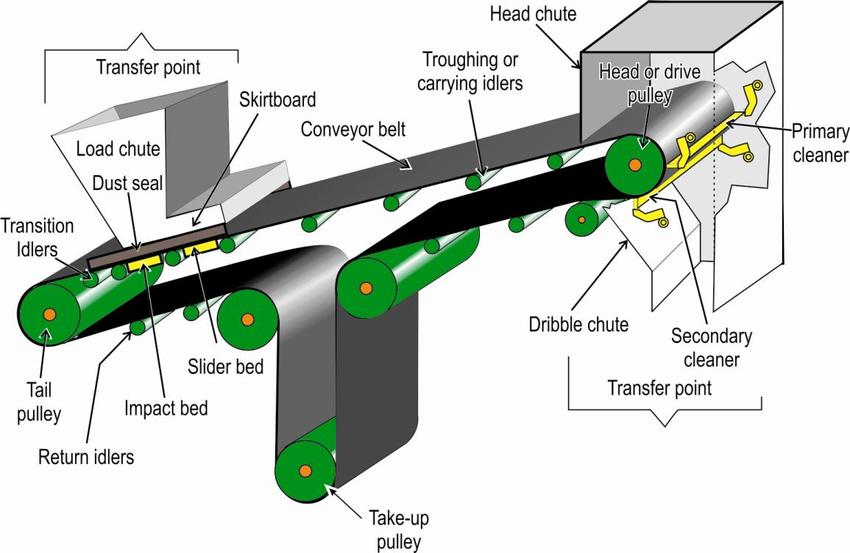

The belt conveyor is mainly composed of two end rollers and a closed conveyor belt tightly sleeved thereon. The roller that the belt conveyor belt rotates is called the drive roller (transmission roller); the other roller that only changes the direction of movement of the conveyor belt is called the redirecting roller.

The drive roller is driven by an electric motor through a reducer, and the conveyor belt is dragged by the friction between the drive roller and the conveyor belt. The drive roller is generally installed at the discharge end to increase traction and facilitate dragging. The material is fed from the feeding end, falls on the rotating conveyor belt, and is driven by the friction of the conveyor belt to be transported to the discharge end for discharge.

Structural Composition:

Conveyor belt: usually made of multiple layers of fabric canvas and rubber or plastic, with wear-resistant and tensile-resistant properties.

Drive device: usually located at one end of the conveyor, powered by a motor, reducer, etc.

Support frame: a structure that supports the conveyor belt, usually made of steel structure, used to support the conveyor belt and drive device.

Tensioning device: used to adjust the tension of the conveyor belt to maintain proper tension.

Roller: installed at the bottom of the conveyor to support and guide the conveyor belt.

Guide device: ensures that the conveyor belt maintains the correct track during operation.

Cleaning device: used to remove debris and dirt on the conveyor belt to keep the conveyor belt clean.

| Conveyor Belt Width (W) | 300mm, 400mm, 500mm, 600mm, etc CUSTOMIZED |

| Conveyor Belt Length (L) | 1000mm~5000mm, or customed |

| Conveyor Height (H) | 100mm~3500mm, or customed |

| Standard Speed (S) | 5~20 meter/minute |

| Conveyor Roller | stainless steel,galvanized steel, rubber coated roller |

| Belt Material | PVC, PU, Teflon |

| Belt Color | Green, white, black, blue |

| Frame | Stainless Steel,Carton Steel,Aluminum Profile |

| Load-bearing Per Meter | 100KG/meter, or custom |

| Drive Type | Conveyor drived by motor |

| Available Function | Height adjustable, speed adjustable |

Scope of application of belt conveyor:

Belt conveyor is widely used for conveying materials in mining, gravel field, metallurgy, building materials, chemical industry, mineral processing, coal mining and other industries. Belt conveyor and rubber belt conveyor are suitable for conveying powdery, granular, small block low-abrasive materials and bagged materials with a bulk density of less than 1.67/ton/cubic meter, which are easy to take out, such as coal, gravel, sand, cement, fertilizer, grain, etc.

Applicable places of belt conveyor:

Such as: ports, docks, stations, coal yards, warehouses, construction sites, sand and gravel yards, farms, etc., used for short-distance transportation and loading and unloading of bulk materials or single-piece items weighing less than 100 kg.

Thirty years of dedication have allowed us to accumulate extensive production and service experience, enabling us to solve various challenges in powder processing for our numerous clients.

Innovation is the lifeblood of our company's development. To date, we have obtained over 40 domestic and international patents, with many of our products holding multiple patents.

We specialize in undertaking the design and production of fine powder processing production lines, offering a one-stop service from crushing, screening, conveying, feeding, mixing to packaging.

Upon receipt of the products, detailed English user manuals are provided. For relatively complex installations or product usage, video installation guidance is available. For large-scale technical projects, we can dispatch professional technical personnel for on-site installation guidance.

Please fill in the informationWe provide you with personalized solutions

Please fill in the informationWe provide you with personalized solutionsIf you do not know how to select, please call us or leave a message online. We will serve you wholeheartedly!