The bucket elevator is a continuous conveying machine that uses a series of buckets evenly fixed on the endless traction member to transport bulk materials upward in a vertical or nearly vertical direction. It mainly consists of a running part (bucket and traction belt), an upper section with a transmission roller, a lower section with a tensioning roller, an intermediate housing, a drive device, a check brake device, etc. Bucket elevators are mainly suitable for conveying loose density ρ<1.5t/m³ powder, granular and small pieces of non-abrasive and semi-abrasive bulk materials, such as coal, sand, coke, cement, crushed ore, etc.

Vertical conveying, compact structure, small footprint, simple;

Good sealing, can work in a fully enclosed housing;

Large lifting height and conveying volume;

High sensitivity to overload, bucket and traction parts are easily damaged, not suitable for conveying large pieces of materials, must be fed evenly, otherwise it is easy to block.

Bucket elevator selection

Bucket elevators can be divided into belt type and chain type, with compact structure, small footprint and good sealing performance. Belt type bucket elevators are light, flexible, easy to maintain and low noise. They are suitable for conveying powdery and granular materials with a density less than 1.5, and the material temperature is generally below 100 degrees Celsius. Chain bucket elevators are used for conveying powdery and granular materials with large conveying volume and material density greater than 1.5. The material temperature is generally above 100 degrees Celsius.

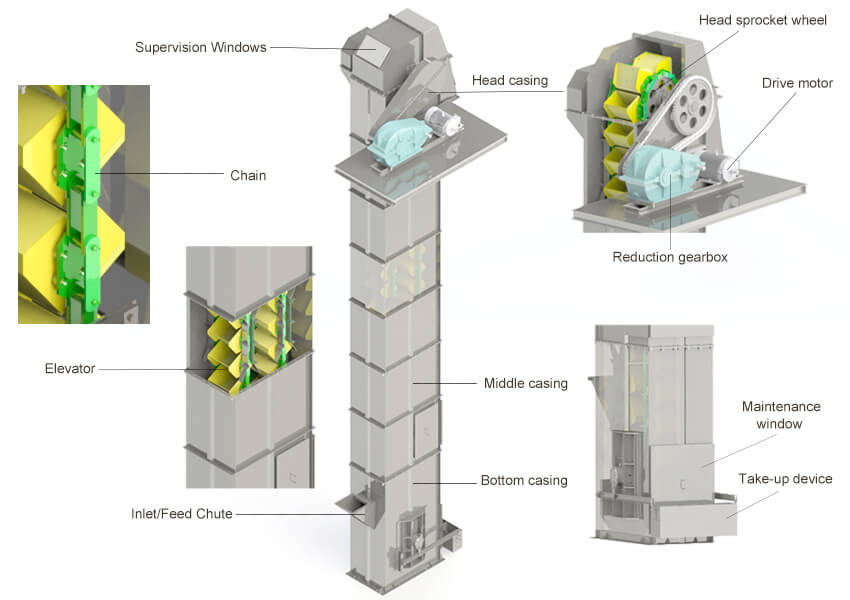

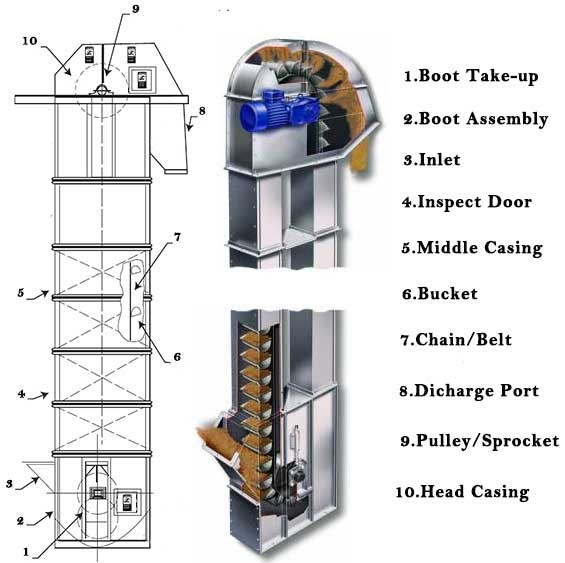

1. Hopper: used to load materials and lift them.

2. Traction member: such as a belt or chain, drives the bucket to move.

3. Drive device: provides power, usually including a motor, reducer, etc.

4. Upper and lower rollers (or sprockets): change the direction of movement of the traction member.

5. Casing: forms a closed conveying channel to prevent material spillage and dust flying.

6.Tensioning device: used to adjust the tension of the traction member to ensure normal operation.

| Model | TD100 | TD130 | TD160 | TD250 | TD315 | TD400 | TD500 | TD600 |

| Speed (m/s) | 0.4-1.4 | |||||||

| Conveying capacity (cubic/hour) | ≤3 | ≤4 | ≤20 | ≤38 | ≤42 | ≤68 | ≤96 | ≤148 |

| Lifting height (m) | ≤12 | |||||||

Bucket elevators are widely used, including the following industries:

1. Building materials industry: In the transportation of materials such as cement, limestone, gypsum, etc., bucket elevators are the most common and effective conveying equipment. They can transport raw materials from storage tanks or loading equipment to various work stations, and can also transport finished products to warehouses or packaging areas.

2. Chemical industry: In the chemical industry, bucket elevators are mainly used to transport granular materials such as alumina, potassium sulfate, potassium dihydrogen phosphate, calcium carbonate, etc. It can also be used to transport liquid materials.

3. Metallurgical industry: In the metallurgical industry, bucket elevators are usually used to transport materials such as iron ore, coke, lime, etc. in processes such as ironmaking, steelmaking, and casting.

4. Food industry: In the food industry, bucket elevators are mainly used to transport bulk materials such as grains, peanuts, and soybeans, and are widely used in flour processing, feed processing, dairy processing, and other fields.

Mining industry: In the mining industry, bucket elevators are usually used to transport bulk materials such as ore and coal from the wellhead to the ground or transport them to other process equipment.

Thirty years of dedication have allowed us to accumulate extensive production and service experience, enabling us to solve various challenges in powder processing for our numerous clients.

Innovation is the lifeblood of our company's development. To date, we have obtained over 40 domestic and international patents, with many of our products holding multiple patents.

We specialize in undertaking the design and production of fine powder processing production lines, offering a one-stop service from crushing, screening, conveying, feeding, mixing to packaging.

Upon receipt of the products, detailed English user manuals are provided. For relatively complex installations or product usage, video installation guidance is available. For large-scale technical projects, we can dispatch professional technical personnel for on-site installation guidance.

Please fill in the informationWe provide you with personalized solutions

Please fill in the informationWe provide you with personalized solutionsIf you do not know how to select, please call us or leave a message online. We will serve you wholeheartedly!