The 450 filter vibrating screen is a compact and mobile vibration screening machine designed for efficient powder classification and liquid filtration. With its single-layer screen, it is ideal for applications involving powder screening and slurry filtration where the content of large particles is minimal. This device is characterized by its low noise operation and small footprint.

Compact Design: Space-saving and easy to move with a generally equipped trolley.

Simple Structure: Low maintenance requirements.

Ease of Use: One-button switch for simple operation.

Convenient Handling: Top feeding and bottom discharging for user convenience.

Fine Mesh Screening: Available in various mesh sizes to meet specific filtration needs.

Durability: Constructed from stainless steel for a smooth, easy-to-clean surface and extended equipment lifespan.

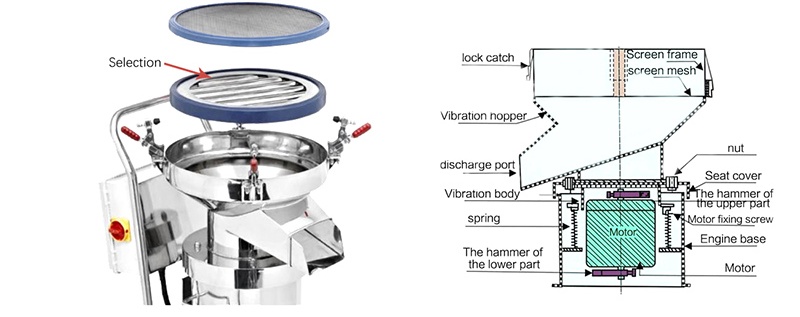

The 450 filter vibrating screen employs an innovative vertical vibration motor as its vibration source. Eccentric weights are mounted at both ends of the motor, enabling it to produce a three-dimensional motion—horizontal, vertical, and inclined. This motion is transferred to the screen frame and materials, ensuring thorough classification. By adjusting the phase angle of the upper and lower eccentric weights, the material's trajectory on the screen surface can be altered to achieve optimal classification

The 450 filter consists of a body, vibration, lower hopper, screen basket, and electronic control. The machine adopts a new vibration structure, which is stable and efficient. The screen basket is easy to operate, clean, and change. The machine has a novel appearance, a reasonable structure, and is easy to use. It is more suitable for occasions where the work location changes frequently.

| Model | Diameter | Frequency | Dimension | Power | Voltage | Weight |

| 450 | 400mm | 1460times/min | 500*450*600 | 0.18kw | 380V | 40kg |

The filter vibrating screen is ideal for single-layer screening and filtering across various industries, specifically for processing materials with low production volumes or minimal impurities.

1. Food and Beverage Industry: Efficiently filters liquids such as juice, wine, milk, and soy sauce to remove impurities and suspended matter, ensuring product quality and taste.

2. Chemical Industry: Filters chemical raw materials, solutions, coatings, and pigments to eliminate particles, impurities, and solid matter, ensuring production process stability and product purity.

3. Oil and Gas Industry: Filters solid particles, impurities, and sediments from oil, natural gas, and liquefied gas, protecting pipelines and equipment for smooth operation.

4. Sewage Treatment: Used in sewage treatment plants' pretreatment processes to filter solid particles and suspended matter, purifying water and reducing the burden on subsequent treatment stages.

Thirty years of dedication have allowed us to accumulate extensive production and service experience, enabling us to solve various challenges in powder processing for our numerous clients.

Innovation is the lifeblood of our company's development. To date, we have obtained over 40 domestic and international patents, with many of our products holding multiple patents.

We specialize in undertaking the design and production of fine powder processing production lines, offering a one-stop service from crushing, screening, conveying, feeding, mixing to packaging.

Upon receipt of the products, detailed English user manuals are provided. For relatively complex installations or product usage, video installation guidance is available. For large-scale technical projects, we can dispatch professional technical personnel for on-site installation guidance.

Please fill in the informationWe provide you with personalized solutions

Please fill in the informationWe provide you with personalized solutionsIf you do not know how to select, please call us or leave a message online. We will serve you wholeheartedly!