The ultrasonic vibrating screen is a high-precision screening device specifically designed for fine powder applications, capable of screening up to 600 mesh. This advanced technology is widely utilized across various industries, including chemical, pharmaceutical, food, papermaking, metallurgy, building materials, rubber, and machinery. It effectively handles powders with strong adsorption, easy agglomeration, high static electricity, and light specific gravity. The screen features a long service life, a fully enclosed structure to prevent dust spillage, and user-friendly operation and maintenance.

Continuous Operation

Ultrasonic waves can work continuously for 12-24 hours without cooling.

High Precision

The screening mesh can reach up to 600 mesh.

Efficient Cleaning

Ultrasonic waves clean the screen, ensuring easy operation and maintenance.

Problem-Solving Technology

Effectively addresses screening challenges of strong adsorption, easy agglomeration, high static electricity, high fineness, high density, and light specific gravity.

The ultrasonic vibrating screen operates by converting 220V, 50HZ or 110V, 60HZ electrical energy into 38KHZ high-frequency electrical energy. This energy is then input into the ultrasonic transducer, enhancing screening efficiency and net cleaning. The system introduces a low-amplitude, high-frequency ultrasonic vibration wave (mechanical wave) on the screen, superimposed with a high-frequency, low-amplitude ultrasonic vibrator. This creates a substantial ultrasonic acceleration, keeping the material on the screen surface in a suspended state. This process suppresses adhesion, friction, flat drop, and other blocking factors, resolving screening issues associated with strong adsorption, easy agglomeration, high static electricity, high fineness, high density, and light specific gravity. As a result, the ultrasonic vibrating screen is ideal for screening ultra-fine powders with high precision.

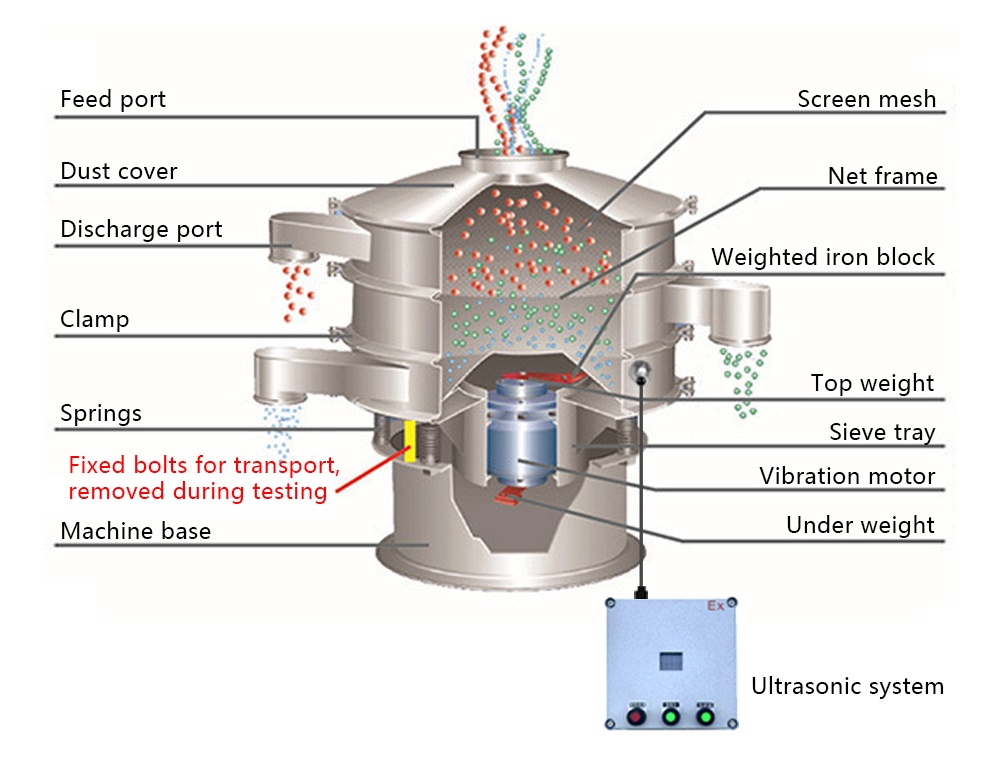

1. Ultrasonic transducer: convert low-frequency electrical energy into high-frequency, low-amplitude ultrasonic waves.

2. Ultrasonic special grid: the grid structure is equipped with a resonance ring to convert ultrasonic waves into high-frequency, low-amplitude mechanical waves, which are then transmitted to the surface of the screen.

3. Ultrasonic power supply: the output power and frequency of the ultrasonic wave can be adjusted.

4. Screen, screen frame, exciter, base: the screen is woven, and the screen frame, exciter, base and ordinary rotary vibrating screen have the same structure.

| Model | Power(kw) | Effective diameter for sieve surface(mm) | Packing size(mm) | Layer(s) |

| SYC-400 | 0.25 | Φ380mm | 600*600*500 | 1-5 |

| SYC-600 | 0.55 | Φ580mm | 800*800*680 | 1-5 |

| SYC-800 | 0.75 | Φ780mm | 1160*1160*880 | 1-5 |

| SYC-1000 | 1.1 | Φ970mm | 1360*1360*980 | 1-5 |

| SYC-1200 | 1.5 | Φ1170mm | 1850×1850×1130 | 1-5 |

| SYC-1500 | 2.2 | Φ1470mm | 2200×2200×1360 | 1-5 |

Ultrasonic vibrating screen is suitable for screening high-precision, high-static, high-density, light-weight materials.

1. Food industry: flour, sugar, vegetable protein, milk powder, salt, five-spice powder, pepper, pepper powder, monosodium glutamate

2. Chemical industry: plastic powder, rubber powder, pigment, filler, resin powder, polytetrafluoroethylene powder

3. Metallurgical industry - alloy powder, (gold, silver, copper, aluminum, nickel, chromium, magnesium, zinc, barium, vanadium, chrysanthemum, strontium. Lead) powder, casting sand, etc.

4. Pharmaceutical industry - Western medicine powder, Chinese medicine powder, pharmaceutical intermediates, pearl powder, etc.

Thirty years of dedication have allowed us to accumulate extensive production and service experience, enabling us to solve various challenges in powder processing for our numerous clients.

Innovation is the lifeblood of our company's development. To date, we have obtained over 40 domestic and international patents, with many of our products holding multiple patents.

We specialize in undertaking the design and production of fine powder processing production lines, offering a one-stop service from crushing, screening, conveying, feeding, mixing to packaging.

Upon receipt of the products, detailed English user manuals are provided. For relatively complex installations or product usage, video installation guidance is available. For large-scale technical projects, we can dispatch professional technical personnel for on-site installation guidance.

Please fill in the informationWe provide you with personalized solutions

Please fill in the informationWe provide you with personalized solutionsIf you do not know how to select, please call us or leave a message online. We will serve you wholeheartedly!