The screw feeder mainly are divided into three types: horizontal, inclined and vertical.this uses the rotating spiral blades to push the materials for spiral conveying. There are many choices of blade specifications, such as solid surface type, belt surface type, blade surface type, etc., which can be selected according to the different materials to be conveyed. It is suitable for powder particle feeding and is suitable for feeding equipment with certain high requirements in various industries. It adopts closed conveying of materials with good sealing performance, which can avoid dust pollution to the environment and reduce material reflux.

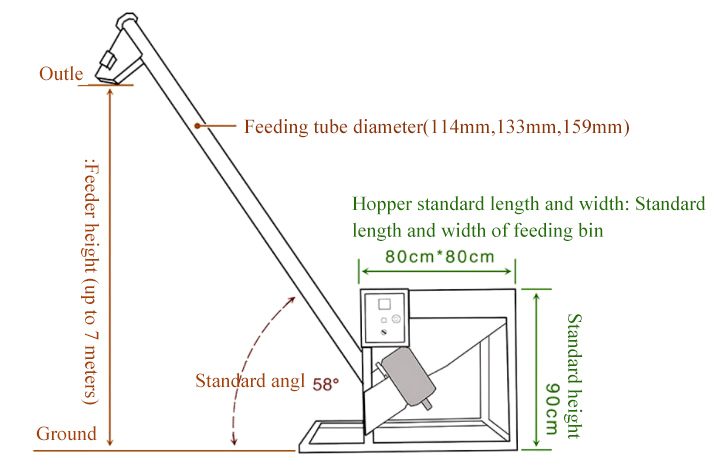

The spiral feeder can be customized according to the needs, and can choose inclined or vertical feeding. It can also be simply equipped with a mobile shelf for easier movement. The feed port of the feeder is designed with a material joint (which can be round or square) to facilitate feeding. It can be used alone or directly connected and fixed with its supporting equipment. It does not require a foundation and occupies a small area.

This machine is particularly suitable for conveying various powder materials, and can also be used to convey various granular or flaky materials.

Adopt uniquely designed stainless steel spiral blades.

High conveying capacity, safe and reliable operation, easy disassembly and cleaning.

Good adaptability and long service life.

Good sealing quality and good rigidity.

Can be customized according to customer requirements.

Vibrator can be added to increase feeding speed.

Pour the raw materials into the material box of the spiral feeder, start the switch, and the motor drives the rotating shaft to start rotating.

Then the material is rotated. Under the friction between the material and the inner wall of the casing, the material is continuously lifted up from the bottom of the material box to the discharge port by the screw. The system is equipped with a time setting, and the feeding time can be set according to the amount of material fed each time.

A screw conveyor is a spiral-shaped bulk material transport system that moves raw materials to processing areas located on different levels of a facility. These conveyors are inclined at different angles to economically lift and transport materials up and down floors. They require ample space and more power to lift the material, depending on the steepness of the angle.

Screw: It is the core component of the screw conveyor, responsible for conveying materials from one end to the other. The screw can be selected with different materials (such as carbon steel, stainless steel, etc.) and pitches according to the material characteristics and conveying distance requirements.

Conveying pipeline: It is used to fix and support the screw. At the same time, the design of the conveying pipeline can determine the parameters such as diameter, length and material according to the characteristics of the material and the conveying distance.

Motor and transmission device: It is used to drive the rotation of the screw. Usually, an electric motor is used as the power source, and the power is transmitted to the screw through the transmission device.

Support frame and bearing: The support frame is used to support the conveying pipeline and the screw, and the bearing is installed on the support frame to support the rotation of the screw.

Feed port and discharge port: The feed port is used to add materials to the screw conveyor, and the discharge port is used to discharge materials.

Safety equipment: Including protective covers, safety switches, etc., to ensure the safety of operators and equipment.

1. Choose the appropriate model according to different process requirements

If it is a small angle, horizontal, short-distance conveying, a horizontal screw feeder can be selected. If it is a vertical or large angle conveying with a small height, a vertical screw feeder should be selected.

2. Determine the form of the spiral blade according to the different materials being conveyed

a. The spiral blades of the solid spiral are mainly used to convey small particles or powdered materials that are dry and have low viscosity, such as lime powder, coal powder, etc.

b. The spiral blades of the belt spiral are mainly used to convey blocky or medium-viscosity materials, such as sludge, etc.

c. The blade-type spiral blades are mainly used to convey tough or compressible materials.

3. Determine the direction of rotation of the spiral blade, the spiral shaft and the direction of rotation, and the combination of the spiral body according to the requirements of the process equipment

The direction of material conveying can be determined by determining the position of the conveyor head and tail end. The direction of rotation of the spiral blade and the direction of the shaft must meet the requirements. If unloading is carried out in the middle or at both ends, a combination of blades with different directions of rotation should be used to weigh a spiral body.

Carbon steel feeder is a commonly used material and is widely used. Carbon steel material has low cost, large flow rate, good heat insulation effect, no cooling device is required, and low power consumption, but it will be a little worse in anti-sleeping and anti-dwarfing effects, but it can also achieve normal material transportation

Made of SUS3041316 stainless steel, it is mostly used in industries or enterprises with high requirements for sanitary environment such as food and medicine. Stainless steel is acid-resistant, corrosion-resistant, and wear-resistant. The surface of the spiral pipe is flat without depressions or undulating waves, and there is no distortion or deformation. It is also convenient to clean after use. Its life is longer than that of carbon steel.

Spiral feeder can be processed and designed according to conveying materials, conveying length, import and export distance, conveying volume, installation inclination angle, etc.

| Model | Screw diameter(mm) | Screw pitch (mm) | Rotational speed of screw(r/min) | Convey measure(m3/h) | Motor power(kw) | Max dip angle(o ) |

| LS0-100 | 100 | 100 | 140 | 2.2 | 2.2~18.5 | ≤20 |

| LS-125 | 125 | 125 | 125 | 4 | ||

| LS-160 | 160 | 160 | 112 | 8 | ||

| LS-200 | 200 | 200 | 100 | 11 | ||

| LS-250 | 250 | 250 | 90 | 22 | ||

| LS-315 | 315 | 315 | 80 | 34 | ||

| LS-400 | 400 | 355 | 71 | 64 | ||

| LS-500 | 500 | 400 | 63 | 95 | ||

| LS-630 | 630 | 450 | 50 | 150 | ||

| LS-800 | 800 | 500 | 40 | 210 |

Screw conveyor is suitable for conveying powder, granular, small block and other series of materials in industry, food, environmental protection, medicine and other industries.

Chemical industry: coatings, inks, color pastes, paints, latex paints, aluminum powder pastes.

Food industry: starch, soy milk, juice, beverages, dairy products, condiments.

Building materials industry: tailings, coal, metallurgy, sand and gravel

Thirty years of dedication have allowed us to accumulate extensive production and service experience, enabling us to solve various challenges in powder processing for our numerous clients.

Innovation is the lifeblood of our company's development. To date, we have obtained over 40 domestic and international patents, with many of our products holding multiple patents.

We specialize in undertaking the design and production of fine powder processing production lines, offering a one-stop service from crushing, screening, conveying, feeding, mixing to packaging.

Upon receipt of the products, detailed English user manuals are provided. For relatively complex installations or product usage, video installation guidance is available. For large-scale technical projects, we can dispatch professional technical personnel for on-site installation guidance.

Please fill in the informationWe provide you with personalized solutions

Please fill in the informationWe provide you with personalized solutionsIf you do not know how to select, please call us or leave a message online. We will serve you wholeheartedly!