Rigid impeller feeder is commonly known as discharger, also called ash discharge valve. It is mainly used in dust removal, dust cleaning and packaging machines in power plants, cement plants, chemical plants and other industries, and is used as air lock or quantitative feeding when conveying dry powder materials. It can also be used to discharge ash under the ash hopper of dust collectors and air preheaters. It has a simple structure, stable performance, and is easy to operate and maintain. It is an ideal accessory in the conveying, unloading and batching system.

The discharger adopts the principle of planetary rotation, and the input and output are on the same axis. It is also directly connected to the motor, so it has a compact structure, beautiful and novel shape, small size and light weight.

The discharger operates reliably and smoothly, with low noise, few failures, long life, and the gearing parts are made of ductile iron and bearing steel. Good performance and high wear resistance

The bearings, gear boxes, and valve bodies are away from the influence of high temperature dust. The front and rear cover have good sealing performance to prevent dust leakage and extend the service life of the motor parts and lubrication system.

The impeller feeder has strong overload capacity, small impact resistance and inertia moment, and is suitable for frequent starting and reverse rotation.

During operation, the feed is less at the higher ends, and it is not easy to enter the powder in the bearings, which can avoid unnecessary wear. The old sliding bearings are replaced with rolling bearings, which have obvious energy-saving effects than general impeller feeders.

If users need special specifications, motors, sprocket drives and other dischargers can be made.

The impeller feeder is a key equipment in the pneumatic conveying system. For positive pressure conveying system or negative pressure conveying system, the impeller feeder can feed the conveying pipe evenly and continuously. The impeller feeder is very suitable for positive and negative pressure pneumatic conveying system, pulse dust removal equipment and precision feeding. The impeller feeder has the characteristics of compact structure, beautiful shape, good air locking, stable operation, uniform material dropping, light and energy saving. It can play the role of feeding and locking the airflow. Due to the low-speed rotation of the rotor and the extremely small gap between the rotor and the inner cavity of the shell, the reverse flow of the airflow is effectively prevented, thereby ensuring the stability of the air pressure in the system and the normal discharge of materials.

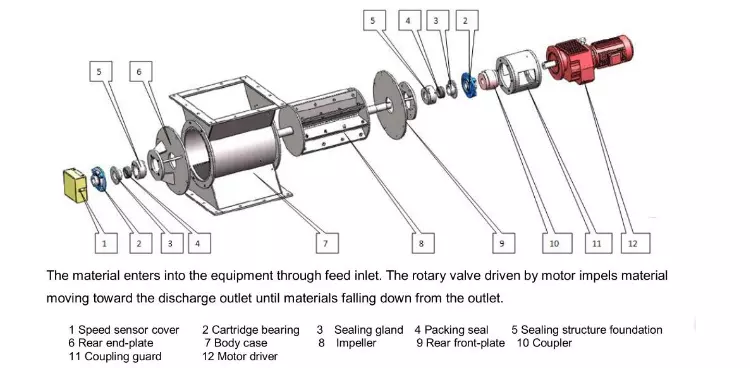

Rigid impeller feeder, rigid impeller feeder is composed of motor, shell, rotor, shaft, gland, impeller, reducer, base, etc. It uses the mechanical rotation principle of the impeller. The material in the upper silo falls into the gap between the blades. With the rotation of the blades, the material in the upper silo of the shell is evenly discharged from the lower part. The rigid impeller feeder can also be customized according to the size of the conveying capacity.

Different Types of Impeller Feeders

Rigid impeller feeders are divided into three categories: ordinary type, pressure-resistant type, and high-temperature type.

Ordinary type

The upper and lower flanges of ordinary impeller feeders are basically square or round, and can also be selected by the user. The ordinary type is generally suitable for materials without wind pressure. It can be used for ordinary materials below 80 degrees and at room temperature. It can continuously and evenly feed materials into the conveying pipe, and in the system and separation dust collection part, it can also serve as a discharger.

Pressure-resistant type

The characteristic of this type of rotary unloading valve is that the end of the rotor blade is made of special wear-resistant material, which can ensure that the end of the blade has good contact with the inner wall of the shell, and the end of the blade can be easily adjusted after wear so that it still maintains good contact with the inner wall of the shell. If a closed rotor is used, it has better air locking performance. The wear-resistant type is mainly suitable for materials with strong grinding performance.

High-temperature type

The temperature of the conveyed material can reach 280℃, and the bearings at both ends are isolated from the impeller to prevent ultra-fine powder from contacting the bearings.

| Model | JL200 | JL300 | JL400 | JL500 | JL630 | JL1000 | ||||||

| Impeller size(mm) | 200×200 | 300×300 | 400×400 | 500×500 | 630×600 | 1000×1000 | ||||||

| Displacement per revolution(m3/r·p·m) | 0.005 | 0.018 | 0.045 | 0.05 | 0.09 | 0.11 | ||||||

| Impeller speed(r·p·m) | 10 | 19 | 19 | 25.5 | 25.5 | 35 | 25 | 35 | 20 | 28 | 20 | 28 |

| Theory feeding capacity(m3/h) | 3 | 6 | 20 | 27 | 68 | 90 | 75 | 105 | 108 | 126 | 154 | 192 |

| Rated feed ability(m3/h) | 2 | 4 | 15 | 20 | 60 | 80 | 70 | 90 | 98 | 110 | 132 | 160 |

| motor power(kw) | 0.75 | 0.75 | 1.5 | 2.2 | 3 | 4 | 4 | 4 | 5.5 | 5.5 | 7.5 | 7.5 |

| Reducer Model | BW1 | BW2 | BW2 | BW3 | BW4 | BW5 | ||||||

| Max material size(mm) | 30 | 45 | 50 | 60 | 75 | 110 | ||||||

| Model | JL200 | JL300 | JL400 | JL500 | JL630 | JL1000 | ||||||

| Impeller size(mm) | 200×200 | 300×300 | 400×400 | 500×500 | 630×600 | 1000×1000 | ||||||

| Displacement per revolution(m3/r·p·m) | 0.005 | 0.018 | 0.045 | 0.05 | 0.09 | 0.11 | ||||||

| Impeller speed(r·p·m) | 10 | 19 | 19 | 25.5 | 25.5 | 35 | 25 | 35 | 20 | 28 | 20 | 28 |

| Theory feeding capacity(m3/h) | 3 | 6 | 20 | 27 | 68 | 90 | 75 | 105 | 108 | 126 | 154 | 192 |

| Rated feed ability(m3/h) | 2 | 4 | 15 | 20 | 60 | 80 | 70 | 90 | 98 | 110 | 132 | 160 |

| motor power(kw) | 0.75 | 0.75 | 1.5 | 2.2 | 3 | 4 | 4 | 4 | 5.5 | 5.5 | 7.5 | 7.5 |

| Reducer Model | BW1 | BW2 | BW2 | BW3 | BW4 | BW5 | ||||||

| Max material size(mm) | 30 | 45 | 50 | 60 | 75 | 110 | ||||||

Rigid impeller feeder is used to continuously and evenly feed dry powdered materials or small granular materials in the upper silo to the next equipment. It is a quantitative feeding equipment. Impeller feeder is widely used as feeding equipment in the material system of cement, building materials, chemical industry, metallurgy and light industry. Special motors can be configured according to user needs, such as explosion-proof, frequency modulation, speed regulation, marine motors, etc. to meet user's special requirements. The material can also be specially processed according to user needs, such as high humidity resistance, corrosion resistance, stainless steel, flexible blades, explosion-proof impellers, etc.

Q1: Notes on Impeller Feeder Selection

1. Name of the conveyed material, specific gravity of the material, whether the material is powder or granular.

2. Conveying capacity. The size of the impeller feeder and the speed ratio of the reducer can be selected according to the conveying capacity. Determine the output of the impeller feeder. According to the output, you can choose an impeller feeder with a suitable caliber. Select the appropriate caliber for the impeller feeder. The normal impeller feeder has a round or square mouth on both the top and bottom. When customized, it can be made into a round top and a square bottom or a round top and a square bottom.

3. After determining the basic model of the impeller feeder, it is necessary to pay attention to whether the working environment of the impeller feeder has "positive pressure" or "negative pressure". When there is wind pressure, the impeller feeder must be selected as a wind-locking type. Generally, there is a mechanical wind lock, which is to mechanically finish the impeller and valve body of the impeller feeder. After finishing, the gap is small. When working, the material fills the gap to achieve the purpose of wind locking. There are also flexible wind locks. Depending on the material, you can choose wear-resistant canvas belts and thin stainless steel sheets, fixed to the impeller rim, 5-10mm beyond the rim, and rely on the deformation of the stainless steel sheet or canvas belt to block the gap between the rim and the valve body during rotation to achieve the purpose of wind locking.

4. Is there high pressure in the working conditions of the impeller feeder? If there is high pressure, the impeller feeder valve body and the impeller outer circle of the impeller feeder need to be finely processed to achieve the purpose of wind locking and wind shutting.

Q2: Use, installation and commissioning:

1. Installation precautions

⑴ The entire impeller feeder must be kept clean, especially there must be no foreign matter in the shell.

⑵ Check all fasteners to ensure reliable connection and good grounding of the machine (including the motor).

⑶ The upper and lower flanges of the entire impeller feeder must be firmly connected, and the whole machine must be in a horizontal state.

⑷ Check the motor wiring to make it ready for starting.

2. Operation precautions

⑴ If the motor heats up too high when the power is turned on, the machine must be stopped for inspection to avoid affecting the normal operation of the reducer.

⑵ The reducer should be used according to the reducer manual, and the motor should turn in the direction indicated by the arrow.

⑶ If powder leakage is found on the shaft, the packing gland bolts at both ends should be tightened.

⑷ During operation, check the heating of the bearing. Generally, the temperature rise of the bearing should not exceed 60℃

⑸ If abnormal vibration is found during operation, stop the machine to eliminate it.

⑹ If the bolts are found to be loose during operation, they should be tightened in time.

Thirty years of dedication have allowed us to accumulate extensive production and service experience, enabling us to solve various challenges in powder processing for our numerous clients.

Innovation is the lifeblood of our company's development. To date, we have obtained over 40 domestic and international patents, with many of our products holding multiple patents.

We specialize in undertaking the design and production of fine powder processing production lines, offering a one-stop service from crushing, screening, conveying, feeding, mixing to packaging.

Upon receipt of the products, detailed English user manuals are provided. For relatively complex installations or product usage, video installation guidance is available. For large-scale technical projects, we can dispatch professional technical personnel for on-site installation guidance.

Please fill in the informationWe provide you with personalized solutions

Please fill in the informationWe provide you with personalized solutionsIf you do not know how to select, please call us or leave a message online. We will serve you wholeheartedly!