Hammer crusher is a kind of equipment that crushes materials in the form of impact, divided into single rotor and double rotor. It can directly crush materials with a maximum particle size of 600-1800 mm to a particle size of 25 mm or smaller. It is mainly used in cement, chemical, electric power, metallurgy and other industries for medium and fine crushing of medium hardness materials such as limestone, slag, coke, coal, etc.

Model: PC400×300-PC1200×1000

Application range: Applied to the crushing of bulk materials in industries such as metallurgy, building materials, mining, highways, and mineral processing.

High-quality hammer and seal design: large diameter working hammer, wear-resistant and impact-resistant, adjustable particle size; good body sealing, effectively suppress dust and ash leakage, and ensure clean production.

Efficient and compact: small size, light weight, streamlined structure, easy to operate and maintain, excellent production capacity.

Large crushing ratio: The crushing ratio of the hammer crusher is generally 10-25, and the highest can reach 50, which is suitable for large-scale production.

Uniform product: The particle size of the crushed material is uniform, and there is less over-powdering.

Wide applicability: It is specially used for crushing brittle and medium-hard (≤150MPa) materials to meet various industrial needs.

1. Hammer rotation: The motor drives the rotor to rotate at high speed, and the multiple hammers installed on the rotor move accordingly.

2. Material feeding: The material enters the crushing chamber evenly from the feed port.

3. Impact crushing: The material entering the crushing chamber is impacted and sheared by the high-speed rotating hammer and crushed into smaller particles.

4. Second impact: The crushed material is thrown to the wall plate or impact plate of the crushing chamber, and is impacted and crushed by the hammer again. This process can be repeated many times.

5. Discharging: Finally, the material crushed to the required particle size is discharged from the crushing chamber through the discharge port.

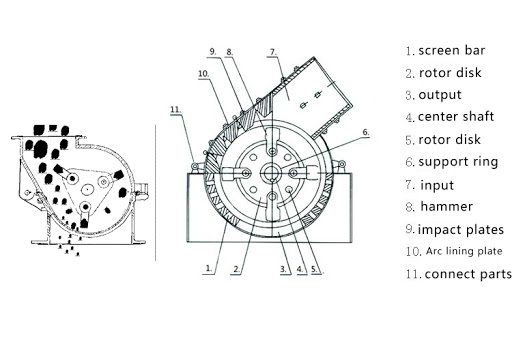

The hammer crusher is mainly composed of a housing, a rotor, a hammerhead, an impact liner, a screen plate, etc. It has the characteristics of a simple structure, lightweight, easy operation and maintenance, etc. Among them, the rotor is composed of a main shaft, a hammer plate, a pin shaft, a hammerhead, etc., and is the main working part of the crusher. In order to prevent ash leakage, a shaft seal is installed at any part of the housing that contacts the shaft.

| Model | Feed size (mm) | Discharge size (mm) | Rotor speed (r/min) | Output (t/h) | Power (kW) | Weight (excluding motor) |

| PC400x300 | <200 | <25 | 1000 | 8-15 | 11 | 0.8 |

| PC500x350 | <200 | <25 | 1000 | 12-20 | 18.5 | 1.2 |

| PC600x400 | <250 | <25 | 1200 | 15-30 | 22 | 1.5 |

| PC800x600 | <300 | <30 | 1100 | 25-50 | 55 | 3.7 |

| PC1000x800 | <300 | <30 | 1000 | 30-65 | 110 | 6.5 |

| PC1000x1000 | <300 | <30 | 800 | 45-80 | 132 | 7.59 |

| PC1200x1000 | <300 | <30 | 650 | 70-100 | 160 | 12.5 |

The discharge of hammer crusher can reach less than 5mm, which is suitable for feeding dry materials. Hammer crusher is mainly used in various fields such as mining, construction, highway, etc. It can crush limestone, construction waste, red brick, concrete, coal gangue, slag, coke and other materials. It is also suitable for crushing wood and paper with strong fiber structure, elasticity and toughness, or crushing asbestos cement waste to recover asbestos fiber, etc. In addition, hammer crusher can not only be used in crushing production line and sand making production line, but also can replace cone crusher in mineral processing production line.

Thirty years of dedication have allowed us to accumulate extensive production and service experience, enabling us to solve various challenges in powder processing for our numerous clients.

Innovation is the lifeblood of our company's development. To date, we have obtained over 40 domestic and international patents, with many of our products holding multiple patents.

We specialize in undertaking the design and production of fine powder processing production lines, offering a one-stop service from crushing, screening, conveying, feeding, mixing to packaging.

Upon receipt of the products, detailed English user manuals are provided. For relatively complex installations or product usage, video installation guidance is available. For large-scale technical projects, we can dispatch professional technical personnel for on-site installation guidance.

Please fill in the informationWe provide you with personalized solutions

Please fill in the informationWe provide you with personalized solutionsIf you do not know how to select, please call us or leave a message online. We will serve you wholeheartedly!