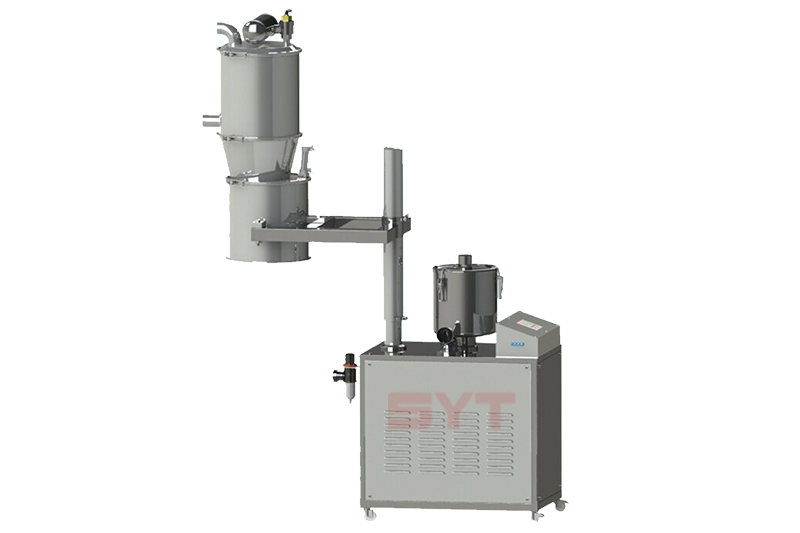

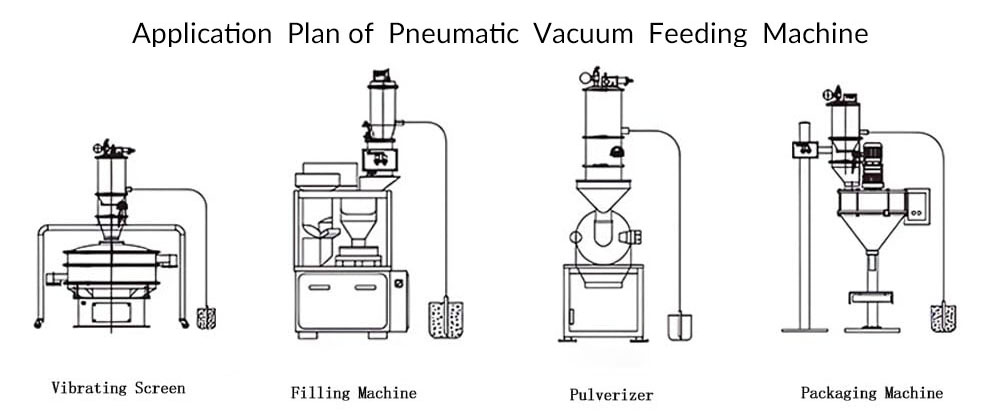

The vacuum feeding machine is specially designed for vacuum conveying of powdered, granular, and powder-granular mixtures. It can efficiently and automatically convey various raw materials to the hoppers of packaging machines, injection molding machines, pulverizers and other production equipment. It can also directly convey the materials to be mixed to the mixer (V-type mixer, two-dimensional mixer, three-dimensional mixer) to achieve seamless connection before material mixing. The vacuum feeder effectively solves the problem of dust leakage that is easily generated during the traditional feeding process. It is a key equipment to help pharmaceutical factories and food factories successfully pass GMP certification and promote a clean and civilized production environment.

Vacuum feeding machine are divided into two types: intermittent discharge and continuous discharge. Intermittent discharge mode is cost-effective and convenient for material level management, suitable for a variety of application scenarios. Continuous discharge mode is designed for long-distance, high-volume material conveying tasks to ensure the continuity and efficiency of material conveying.

Efficient oil-free power: vortex air pump power source, oil-free and water-free design, low maintenance cost, and long-term stable operation.

Fully enclosed and dust-free: closed system transportation, isolated from dust pollution, to ensure a clean production environment and employee health.

Modular and easy to maintain: building block structure, quick-open clamp connection, simplified assembly, disassembly and cleaning processes, and improved maintenance efficiency.

Energy saving, environmental protection and low noise: low energy consumption, good noise control, in line with modern enterprise energy-saving and environmental protection standards, providing a comfortable working environment.

S-shaped flange anti-overflow: the unique S-shaped flange design enhances stability, improves sealing performance, effectively prevents dust overflow, and ensures the purity and safety of materials.

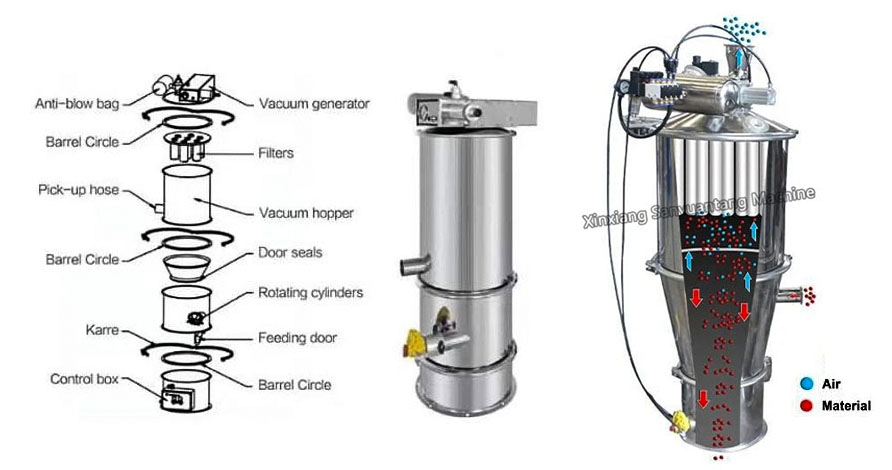

The working principle of the vacuum feeder is based on negative pressure pneumatic conveying technology. The compressed air forms negative pressure in the hopper to attract and promote the efficient flow of materials in the sealed pipeline. It is also supplemented by intelligent material level control to ensure accurate and dust-free delivery of materials. Transported to the designated location, the automation and cleanliness of material transport are realized.

The vacuum feeding machine is complete, consisting of high-pressure air pump, corrosion-resistant stainless steel suction nozzle, flexible conveying hose, high-efficiency PE filter (or 316L stainless steel filter to meet higher cleanliness requirements), compressed air backflush cleaning system, pneumatically controlled precise discharge door, large-capacity vacuum hopper and intelligent material level automatic monitoring device and other precision components. The overall design is ingenious and the workmanship is exquisite.

(1) Pulse backflush system: The special pulse backflush system improves the backflush efficiency and extends the service life of the filter element.

(2) Filtration system: The filter element is made of polyester film material, and the structural strength and filtration accuracy are improved compared with the traditional filter cloth.

(3) Quick-install connection structure: The quick-install connection structure carefully designed by Shanghai Youwei Design and Processing Team can withstand higher negative pressure, with stable structure, no powder leakage, stable pressure and no deformation.

(4) Control system: Provides a variety of control options such as PLC+touch screen and single-chip microcomputer.

(5) Feeding mechanism: The uniquely designed feeding valve mechanism has higher cost performance, higher vacuum degree and lower replacement cost than the traditional butterfly valve.

| Model | Motor Power | Conveying Capacity |

| (kW) | (Kg/h) | |

| ZKYS-1 | 1.5 | 400 |

| ZKYS-2 | 2.2 | 600 |

| ZKYS-3 | 3 | 1200 |

| ZKYS-4 | 5.5 | 2000 |

| ZKYS-5 | 4 | 3000 |

| ZKYS-6 | 5.5 | 4000 |

| ZKYS-7 | 7.5 | 6000 |

| ZKYS-11 | 11 | 6000 |

l Food processing industry: During food processing and packaging, vacuum feeders are often used to convey powdered or granular materials such as flour, powdered sugar, milk powder, coffee powder, and seasonings. Its closed conveying system can effectively prevent the contamination of food raw materials and ensure the hygiene and safety of food.

l Pharmaceutical industry: In the pharmaceutical industry, vacuum feeders are essential to ensure GMP compliance in drug production. It can safely and efficiently convey raw materials such as APIs, excipients, and drug powders, effectively avoid cross-contamination, and ensure the purity and quality of drugs.

l Chemical industry: Since many chemical raw materials are corrosive, toxic, or flammable and explosive, the closed conveying method of vacuum feeders is particularly important. It can safely convey chemical powders, granules, pigments, dyes and other materials, reduce the risk of personnel exposure to harmful substances, and ensure production safety.

l Plastic industry: During plastic processing, vacuum feeders are often used to convey plastic granules, powders and other raw materials to injection molding machines, extruders and other equipment. Its precise control system can ensure accurate feeding of raw materials and improve production efficiency and product quality.

l Metallurgy and building materials industry: Vacuum feeders are also widely used in the fields of metallurgy and building materials, such as conveying metal powders, ceramic raw materials, glass beads and other materials. Its strong conveying capacity and stability help improve the continuity and automation level of the production line.

l Electronics industry: In the production and assembly of electronic components, vacuum feeders can accurately transport tiny electronic components and raw materials, reduce the risk of static electricity and physical damage, and ensure the quality and reliability of electronic products.

l Ceramics and pigment industry: The conveying of materials such as ceramic powder and pigment powder is also one of the common applications of vacuum feeders. Its dust-free conveying system helps to keep the production environment clean and reduce product defects.

l Feed and agricultural product processing: In the feed and agricultural product processing industry, vacuum feeders are used to convey materials such as grains, beans, feed additives, etc. Its high efficiency and energy-saving characteristics help to improve processing efficiency and product quality.

Thirty years of dedication have allowed us to accumulate extensive production and service experience, enabling us to solve various challenges in powder processing for our numerous clients.

Innovation is the lifeblood of our company's development. To date, we have obtained over 40 domestic and international patents, with many of our products holding multiple patents.

We specialize in undertaking the design and production of fine powder processing production lines, offering a one-stop service from crushing, screening, conveying, feeding, mixing to packaging.

Upon receipt of the products, detailed English user manuals are provided. For relatively complex installations or product usage, video installation guidance is available. For large-scale technical projects, we can dispatch professional technical personnel for on-site installation guidance.

Please fill in the informationWe provide you with personalized solutions

Please fill in the informationWe provide you with personalized solutionsIf you do not know how to select, please call us or leave a message online. We will serve you wholeheartedly!