GZG series Vibrating feeder conveyor uses the synchronization principle of two eccentric vibrating motors to generate a combined force at an angle of 60° to the horizontal plane. Through periodic vibration, it pushes the material in the feeding trough to do throwing or sliding motion, so as to evenly, quantitatively and continuously feed granular, small block and powdery materials from the storage bin to the receiving equipment, such as feeding and batching to crushing, coal selection, screening, transportation, packaging machinery, etc. It is suitable for automatic batching, quantitative packaging and automatic control to realize the automation of flow operation.

It is widely used in mining, metallurgy, coal, thermal power, glass, building materials, light industry, chemical industry, grain and other industries, and is often used in conjunction with vibrating conveyors, vibrating screens, belt conveyors, bucket elevators, crushers, etc.

[Feed particle size]: ≤360mm [Production capacity]: ≤1000th

The product is small in size, low in noise, light in weight, low in power consumption, and easy to install and maintain.

It has a wide range of uses and is suitable for automatic batching, quantitative packaging and automatic control.

The flow rate can be changed and controlled by adjusting the exciting force during use, so it is easy to adjust and the flow rate is stable.

A closed structure can be used to effectively prevent dust spillage and environmental pollution.

The only shortcoming of the equipment is that it is not suitable for use in explosion-proof occasions.

The material will jump in the silo, so the material will have less wear on the feed trough and the feeding capacity is also large.

The equipment starts quickly and quickly, the entire feeding process is very stable, and the shutdown is relatively stable.

The feed particle size is 300-1200mm, and the feeding amount can reach 40-600 tons/hour.

The material flow can be changed and opened and closed instantly, and the feeding amount has a high accuracy.

The material jumps forward continuously along a parabolic trajectory, and the feed trough wears less.

A closed structure can be used to effectively prevent material overflow or avoid pollution to the surrounding area.

The vibrating feeder conveyor uses a special vibration motor to drive the exciter and the feed trough, so that the material makes periodic linear reciprocating vibrations along the inclined direction. When the vertical component of the acceleration of the feed trough is greater than the gravity acceleration, the material in the feed trough will be thrown up and quickly jump forward along the trajectory of the parabola. The material is thrown up and falls, and the continuous excitation of the exciter is repeated to achieve the purpose of feeding.

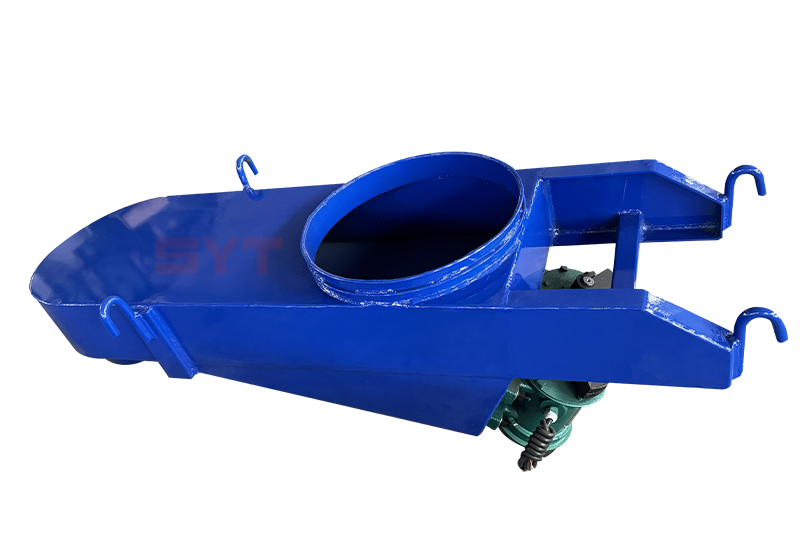

l The vibrating feeder is composed of a trough, a vibrating motor, a shock absorbing device, a lining plate and other parts.

l The trough: It is a load-bearing component used to bear the materials stored in the warehouse. It can be made into an open or closed type according to the use requirements.

l The shock absorbing device: It can effectively isolate the low-frequency vibration caused by the vibration of the equipment operation, effectively eliminate the resonance phenomenon, and can also install a hanging shock absorbing device according to the user's requirements.

l The lining plate: 16Mn lining plate or polymer wear-resistant lining plate, which helps to maintain the trough body.

| Model | Productivity t/h | Feed trough dimensions: width × length × height mm | Operation mode | Particle size mm | Vibration Motor | Weight kg | ||||

| Voltage | Frequency Hz | Model | Power/kW | Vibration frequency | ||||||

| GZG30-4 | 15 | 300×1000×160 | Continuous | 120 | 380 | 50 | YZD2.5-4 | 0.18×2 | 1450 times/min | 110 |

| GZG40-4 | 30 | 400×1200×160 | Continuous | 120 | 380 | 50 | YZD5-4 | 0.25×2 | 1450 times/min | 155 |

| GZG50-4 | 50 | 500×1200×160 | Continuous | 120 | 380 | 50 | YZD8-4 | 0.4×2 | 1450 times/min | 190 |

| GZG60-4 | 80 | 600×1800×180 | Continuous | 180 | 380 | 50 | YZD16-4 | 0.75×2 | 1450 times/min | 410 |

| GZG70-4 | 100 | 700×1800×200 | Continuous | 180 | 380 | 50 | TZP20-4 | 1.1×2 | 1450 times/min | 440 |

| GZG80-4 | 200 | 800×2000×225 | Continuous | 200 | 380 | 50 | TZP32-4 | 1.5×2 | 1450 times/min | 640 |

| GZG90-4 | 300 | 900×1500×300 | Continuous | 250 | 380 | 50 | YZD50-4 | 2.2×2 | 1450 times/min | 730 |

| GZG110-4 | 400 | 1100×1500×300 | Continuous | 250 | 380 | 50 | YZD50-4 | 2.2×2 | 1450 times/min | 900 |

| GZG130-4 | 500 | 1300×1500×400 | Continuous | 350 | 380 | 50 | YZD50-4 | 2.2×2 | 1450 times/min | 1000 |

| GZG70-6 | 80 | 700×1800×200 | Continuous | 150 | 380 | 50 | YZD20-6 | 1.5×2 | 960 times/min | 440 |

| GZG80-6 | 160 | 800×2000×225 | Continuous | 180 | 380 | 50 | YZD30-6 | 2.2×2 | 960 times/min | 670 |

| GZG90-6 | 240 | 900×1500×300 | Continuous | 240 | 380 | 50 | YZD40-6 | 3.0×2 | 960 times/min | 740 |

| GZG110-6 | 320 | 1100×1500×300 | Continuous | 240 | 380 | 50 | YZD50-6 | 3.7×2 | 960 times/min | 940 |

| GZG130-6 | 400 | 1300×1500×400 | Continuous | 320 | 380 | 50 | YZD50-6 | 3.7×2 | 960 times/min | 1040 |

| GZG150-6 | 500 | 1500×1800×500 | Continuous | 320 | 380 | 50 | YZD50-6 | 3.7×2 | 960 times/min | 2000 |

| GZG180-6 | 800 | 1800×1800×500 | Continuous | 320 | 380 | 50 | YZD75-6 | 5.5×2 | 960 times/min | 2590 |

| GZG200-6 | 1000 | 2000×2000×500 | Continuous | 360 | 380 | 50 | YZD75-6 | 5.5×2 | 960 times/min | 3700 |

The motor vibrating feeder is suitable for feeding block, granular and powdery materials from the storage silo to the receiving equipment evenly, quantitatively and continuously. It is widely used in metallurgy, coal chemical industry, building materials, ceramics, abrasives and grinding tools, grain and other industries.

Thirty years of dedication have allowed us to accumulate extensive production and service experience, enabling us to solve various challenges in powder processing for our numerous clients.

Innovation is the lifeblood of our company's development. To date, we have obtained over 40 domestic and international patents, with many of our products holding multiple patents.

We specialize in undertaking the design and production of fine powder processing production lines, offering a one-stop service from crushing, screening, conveying, feeding, mixing to packaging.

Upon receipt of the products, detailed English user manuals are provided. For relatively complex installations or product usage, video installation guidance is available. For large-scale technical projects, we can dispatch professional technical personnel for on-site installation guidance.

Please fill in the informationWe provide you with personalized solutions

Please fill in the informationWe provide you with personalized solutionsIf you do not know how to select, please call us or leave a message online. We will serve you wholeheartedly!