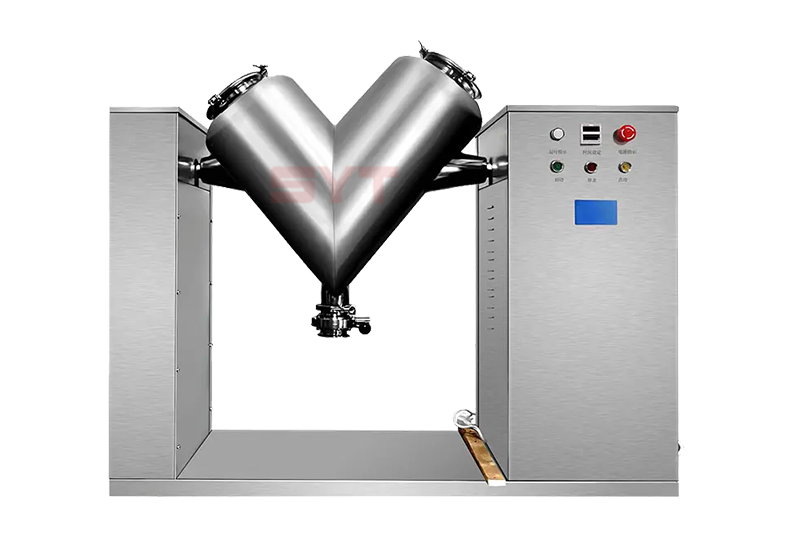

The V-type mixer, with its outer surface and material contact parts made of high-quality stainless steel, is a mixing equipment for the pharmaceutical industry and other powder and granular materials. It is widely used in pharmaceutical, chemical, food, plastic, cosmetic, ceramic, metallurgical and other industries, with simple structure, uniform mixing, high efficiency and no material accumulation. The whole machine has simple structure, easy operation, convenient maintenance and cleaning.

The V-type mixer is suitable for mixing powders and granules with good material fluidity and small physical property differences, as well as for mixing materials with low mixing requirements but short mixing time. Since the material in the V-type mixing container flows smoothly and will not destroy the original shape of the material, the V-type mixer is also suitable for mixing granular materials that are easy to break and wear, or finer powders, blocks, and materials containing a certain amount of water.

The mixing is carried out by gravity diffusion principle, which has little pressure on the material and will not cause shearing and crushing of the material.

The cylinder is made of high-quality stainless steel, and the inner and outer walls are polished. There is no pollution to the material during the mixing process, low power consumption, and easy cleaning.

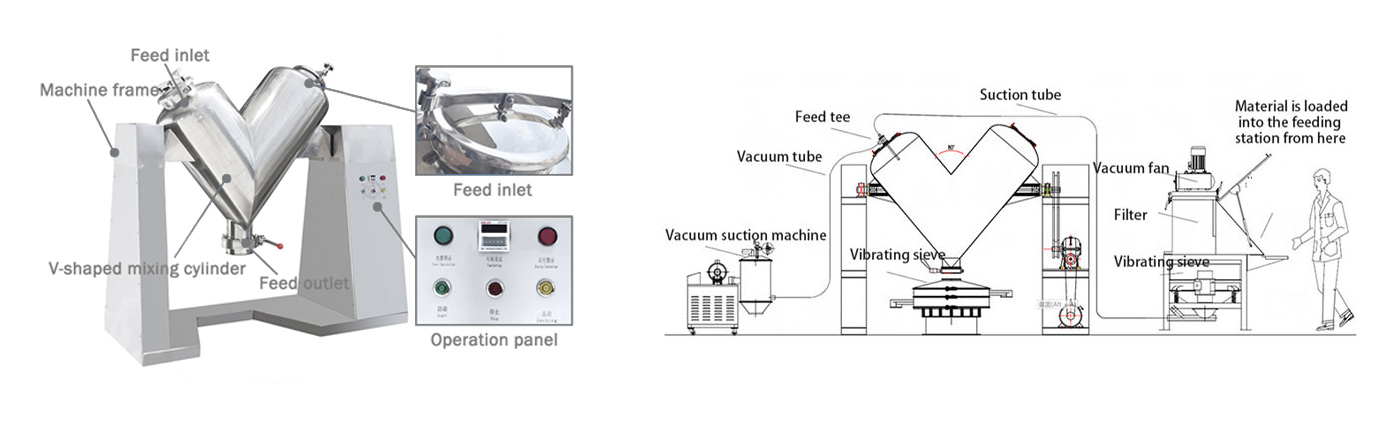

The material is discharged by a stainless steel butterfly valve, and there is no dust leakage or dust flying. 4. The large-volume mixer can be equipped with a vacuum feeding system to improve work efficiency and working environment.

It is particularly suitable for mixing materials with similar particle sizes. Compulsory stirring blades can be added to the V-shaped mixing rotary axis and the V-shaped cylinder to speed up the mixing speed, and it can also be used for mixing easily coagulated materials.

The V-type mixer uses the unequal lengths of the two cylindrical barrels of the mixer, forming an asymmetric shape. When the mixer rotates, the material decomposes and combines, and then decomposes. Due to the different planes of the materials, there is also a lateral force, which pushes the materials to exchange horizontally. For each rotation, the lateral force causes about 25% of the material to flow from one barrel to another barrel. In this way, the materials are mixed horizontally and radially, and the decomposition and combination are carried out mutually, so that the materials can achieve a uniform mixing effect.

The structure of the V-type powder mixer is mainly composed of a frame, a rotating shaft, a rotating device, a hopper and a mixing barrel. Among them, the hopper is used to load the materials to be mixed, the rotating device is used to drive the rotation of the rotating shaft and the mixing barrel, and the mixing barrel is the place where the materials rub and mix with each other.

| Model | GHJ- 180 | GHJ300 | GHJ500 | GHJ1000 | GHJ1500 | GHJ2000 | GHJ2500 | GHJ3000 | GHJ4000 |

| Production capacity (kg/h) | 40 | 60 | 100 | 200 | 300 | 400 | 500 | 600 | 800 |

| Equipped vacuum pump model | WL50 | WL50 | WL50 | WL50 | WL50 | WL50 | WL50 | ||

| Feeding time (min) | 4-6 | 6-9 | 6-10 | 12-18 | 12-18 | 12-18 | 12-18 | ||

| Mixing time (min) | 4-8 | 6-10 | 6-10 | 6-10 | 6-10 | 6-10 | 6-10 | 6-10 | 6-10 |

| Total volume (m3) | 0.18 | 0.3 | 0.5 | 1.0 | 1.5 | 2.0 | 2.5 | 3.0 | 4.0 |

| Cylinder speed (rpm) | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 7.8 | 7.8 |

| Motor power (kw) | 1.1 | 1.1 | 2.2 | 4 | 4 | 7.5 | 7.5 | 7.5 | 11 |

| Dimensions | 178×68×1700 | 188×68×1700 | 250×135×2450 | 305×165× 2700 | 382×190× 3480 | 3990 ×190× 3540 | 399×190×3540 | 469×220×3540 | 495×220×4230 |

| (length × width ×height) | 1750 | 1850 | 2450 | 2940 | 3670 | 3800 | 3800 | 4000 | 4290 |

| (mm) | 290 | 300 | 550 | 850 | 1020 | 2040 | 2200 | 2500 | 2800 |

l Pharmaceuticals: In the pharmaceutical industry, V-type powder mixers are often used to mix drug powders and granules to ensure the uniformity of drug ingredients.

l Chemicals: A variety of powders or granular raw materials in the chemical industry, such as pigments, dyes, catalysts, etc., can be efficiently mixed by V-type mixers.

l Food: Additives, seasonings, milk powder, flour and other powder materials in the food industry are also the main application objects of V-type powder mixers.

l Other industries such as metallurgy, electronics, building materials, etc.: Powders or granular materials in these industries, such as metal powders, electronic materials, building materials, etc., can also be evenly mixed by V-type mixers.

Thirty years of dedication have allowed us to accumulate extensive production and service experience, enabling us to solve various challenges in powder processing for our numerous clients.

Innovation is the lifeblood of our company's development. To date, we have obtained over 40 domestic and international patents, with many of our products holding multiple patents.

We specialize in undertaking the design and production of fine powder processing production lines, offering a one-stop service from crushing, screening, conveying, feeding, mixing to packaging.

Upon receipt of the products, detailed English user manuals are provided. For relatively complex installations or product usage, video installation guidance is available. For large-scale technical projects, we can dispatch professional technical personnel for on-site installation guidance.

Please fill in the informationWe provide you with personalized solutions

Please fill in the informationWe provide you with personalized solutionsIf you do not know how to select, please call us or leave a message online. We will serve you wholeheartedly!