Electromagnetic vibrating feeder is an essential equipment for the automation of assembly line operation. It has a simple structure, is easy to operate, does not require lubrication, consumes little power, can evenly adjust the feeding amount, and is generally used for loose materials. Electromagnetic vibrating feeder is widely used in mining, metallurgy, coal, building materials, chemicals, electricity, grain and other industries to feed block, granular and powdery materials from storage bins or other storage equipment to receiving equipment evenly, continuously or quantitatively.

According to the performance requirements of the equipment, the pressure of the material on the trough should be minimized during the configuration design. According to the manufacturer's requirements, the effective discharge port of the silo should not be greater than one-fourth of the trough width, and the flow rate of the material should be controlled at 6-18m/min. For materials with a large feed volume, a sufficient height of the ore-blocking plate should be set at the discharge of the silo bottom; in order not to affect the performance of the feeder, the ore-blocking plate should not be fixed on the trough.

Small size, light weight, simple structure, easy installation, no rotating parts, no lubrication, easy maintenance, low operating cost.

The resonance principle of mechanical vibration is applied, and the dual mass works in a low critical near-resonance state, so it consumes less electricity.

It can be used in the automatic control workflow to fully realize the automation of the production process, centrally control the process operation, and reduce labor consumption.

The material flow can be changed and opened and closed instantly, and the feeding amount is highly accurate.

The control equipment of the electric vibrator adopts a thyristor half-wave rectifier circuit, which can change and control the feeding amount of the material at any time, and the adjustment is convenient and stable.

The material in the trough is continuously thrown up during operation, so the wear of the feeding trough is small.

The trough made of alloy steel plate can be used to convey high-temperature, severely worn and corrosive materials.

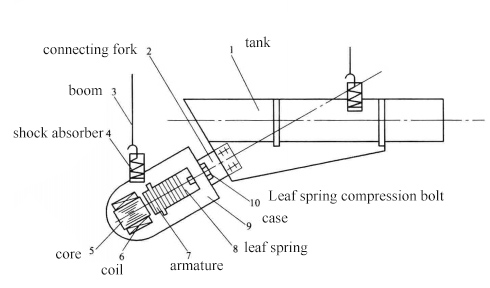

The electromagnetic vibrating feeder is a tuned double-particle near-resonance system that works in a low critical state. When the power is turned on, the electromagnetic coil of the electromagnetic vibrator is powered by a single-phase half-wave rectifier. When the line is connected to the power supply, a voltage is applied to the electromagnetic coil in the positive half cycle, so the electromagnetic coil has a current flowing through it, and a pulse electromagnetic force is generated between the armature and the iron core, which attract each other. In the negative half cycle, the electromagnetic force disappears, and with the help of the potential energy stored in the spring plate, the armature moves in the opposite direction relative to the iron core. In this way, the feeder trough reciprocates along the exciting force direction at the frequency of the AC power supply, and drives the material in the trough body to continuously move forward in a parabolic shape, thereby achieving the purpose of feeding.

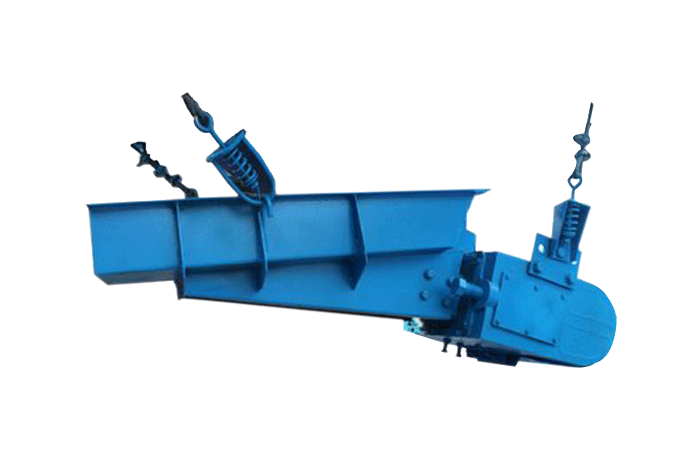

The main components of the electromagnetic vibrating feeder: trough, electromagnetic vibrator, shock absorber, control box.

Customized Selection

Sanyuantang electromagnetic vibrating feeder has a full range of models to meet the different feeding needs of users, including six common models: basic type, upper vibration type, closed type, light trough type, flat trough type and wide trough type.

Selection Instructions

1. When the actual bulk density is greater than or less than the above calculated bulk density, the productivity is converted according to the actual material bulk density.

2. For materials with a particle size less than 1mm, the conveying speed decreases, and wet sticky materials with a moisture content greater than 10% cannot be conveyed normally. If the material layer thickness exceeds a certain actual value, it will hinder normal feeding. The recommended material layer thickness H=(1/3-1/4) trough height.

3. For products with special requirements and special specifications, please contact Sanyuantang Machinery for customized design。

*Electromagnetic vibrating feeder is not suitable for hot materials above 300℃ and occasions with explosion-proof requirements.

| Type | Models | Productivity(t/h) | Feed sizemm | Double Amplitudemm | Supply voltage(V) | Current(A) | power(kw) | Matching control box model | Total weight (kg) | ||

| level | -10° | Working current | Indicates current | ||||||||

| Basic type | GZ 1 | 5 | 7 | 50 | 1.75 | 220 | 1.34 | 1 | 0.06 | XKZ-5G2 | 73 |

| GZ 2 | 10 | 14 | 50 | 3.0 | 2.3 | 0.15 | 146 | ||||

| GZ 3 | 25 | 35 | 75 | 4.58 | 3.8 | 0.2 | 217 | ||||

| GZ 4 | 50 | 70 | 100 | 8.4 | 7 | 0.45 | XKZ-20G2 | 412 | |||

| GZ 5 | 100 | 140 | 150 | 12.7 | 10.6 | 0.65 | 656 | ||||

| GZ 6 | 150 | 210 | 200 | 1.5 | 380 | 16.4 | 13.3 | 1.5 | XKZ-20G3 | 1252 | |

| GZ 7 | 250 | 350 | 250 | 24.6 | 20 | 3 | XKZ-100G3 | 1920 | |||

| GZ 8 | 400 | 560 | 300 | 39.4 | 32 | 4 | 3040 | ||||

| GZ 9 | 600 | 840 | 350 | 47.6 | 38.6 | 5.5 | XKZ-200G3 | 3750 | |||

| GZ 10 | 750 | 1050 | 500 | 39.4×2 | 32×2 | 4×2 | XKZ-200G3 | 6491 | |||

| GZ 11 | 1000 | 1400 | 500 | 47.6×2 | 38.6×2 | 5.5×2 | 7680 | ||||

| Upper vibration type | GZ 3S | 25 | 35 | 75 | 1.75 | 220 | 4.58 | 3.8 | 0.2 | XKZ-5G2 | 242 |

| GZ 4S | 50 | 70 | 100 | 8.4 | 7 | 0.45 | XKZ-20G2 | 457 | |||

| GZ 5S | 100 | 140 | 150 | 12.7 | 10.6 | 0.65 | 666 | ||||

| GZ 6S | 150 | 210 | 200 | 1.5 | 380 | 16.4 | 13..3 | 1.5 | XKZ-20G3 | 1246 | |

| GZ 7S | 250 | 350 | 250 | 24.6 | 20 | 3 | XKZ-100G3 | 1960 | |||

| GZ 8S | 400 | 560 | 300 | 39.4 | 32 | 4 | 3306 | ||||

| Closed type | GZ 1F | 4 | 5.6 | 40 | 1.75 | 220 | 1.34 | 1 | 0.06 | XKZ-5G2 | 77 |

| GZ 2F | 8 | 11.2 | 40 | 3.0 | 2.3 | 0.15 | 154 | ||||

| GZ 3F | 20 | 28 | 60 | 4.58 | 3.8 | 0.2 | 246 | ||||

| GZ 4F | 40 | 56 | 60 | 8.4 | 7 | 0.45 | XKZ-20G2 | 464 | |||

| GZ 5F | 80 | 112 | 80 | 12.7 | 10.6 | 0.65 | 668 | ||||

| GZ 6F | 120 | 168 | 80 | 1.5 | 380 | 16.4 | 13.3 | 1.5 | XKZ-20G3 | 1278 | |

| Light groove type | GZ 5Q | 100 | 140 | 200 | 1.5 | 220 | 12.7 | 10.6 | 0.65 | XKZ-20G2 | 682 |

| GZ 6Q | 150 | 210 | 250 | 380 | 16.4 | 13.3 | 1.5 | XKZ-20G3 | 1326 | ||

| GZ 7Q | 250 | 350 | 300 | 24.6 | 20 | 3 | XKZ-100G3 | 1992 | |||

| GZ 8Q | 400 | 560 | 350 | 39.4 | 32 | 4 | 3046 | ||||

| Flat groove type | GZ 5P | 50 | 70 | 100 | 1.5 | 220 | 12.7 | 10.6 | 0.65 | XKZ-20G2 | 633 |

| GZ 6P | 75 | 105 | 380 | 16.4 | 13.3 | 1.5 | XKZ-20G3 | 1238 | |||

| GZ 7P | 125 | 175 | 24.6 | 20 | 3 | XKZ-100G3 | 1858 | ||||

| Wide groove | GZ 5K1 | 200 | 100 | 1.5 | 220 | 12.7*2 | 10.6*2 | 0.65*2 | XKZ-20G2 | 1316 | |

| GZ 5K2 | 240 | 1343 | |||||||||

| GZ 5K3 | 270 | 1376 | |||||||||

| GZ 5K4 | 300 | 1408 | |||||||||

| GZ 2G | 4 | 50 | 3.0 | 2.3 | 0.15 | XKZ-5G2 | 154 | ||||

| GZ 3G | 10 | 60 | 4.58 | 3.8 | 0.2 | XKZ-5G2 | 234 | ||||

| GZ 4G | 20 | 70 | 8.4 | 7 | 0.45 | XKZ-20G2 | 448 | ||||

| GZ 5G | 40 | 80 | 12.7 | 10.6 | 0.65 | XKZ-20G2 | 668 | ||||

GZ series electromagnetic vibrating feeder is widely used in: mining, metallurgy, coal, building materials, light industry, electricity, machinery, food and other industries, used to feed block, granular and powder materials from silos or funnels to receiving devices evenly, continuously or quantitatively. For example, it can be used with belt conveyors, bucket elevators, screening equipment, crushing equipment, grinding equipment, extrusion equipment, etc.; it can also be used in automatic control processes to implement production process automation.

l Chemical industry: plastic particles, rubber powder, PVC particles

l Abrasive industry: quartz sand, zirconium corundum, silicon carbide

l Pharmaceutical industry: tablets, pharmaceutical powder, pharmaceutical particles

l Food industry: rock sugar, potato chips, cocoa beans

Electromagnetic feeder is a general equipment, according to different industries, the implementation standards are different, such as: food, medical and health standards, can be customized.

Thirty years of dedication have allowed us to accumulate extensive production and service experience, enabling us to solve various challenges in powder processing for our numerous clients.

Innovation is the lifeblood of our company's development. To date, we have obtained over 40 domestic and international patents, with many of our products holding multiple patents.

We specialize in undertaking the design and production of fine powder processing production lines, offering a one-stop service from crushing, screening, conveying, feeding, mixing to packaging.

Upon receipt of the products, detailed English user manuals are provided. For relatively complex installations or product usage, video installation guidance is available. For large-scale technical projects, we can dispatch professional technical personnel for on-site installation guidance.

Please fill in the informationWe provide you with personalized solutions

Please fill in the informationWe provide you with personalized solutionsIf you do not know how to select, please call us or leave a message online. We will serve you wholeheartedly!