LQS airflow screening machine is an efficient fine powder screening equipment, which is good at continuous and accurate screening of powders in the range of 80 to 500 mesh. Its screen design is flexible and can be replaced at any time to meet different needs. LQS airflow screening machine is widely used in chemical, pharmaceutical, food processing, papermaking, metallurgy, building materials, rubber products and machinery manufacturing industries.

LQS airflow screening machine has excellent screening efficiency, large production capacity, fine screening accuracy, and no particle size mixing. The screen is installed vertically to reduce the load-bearing burden and extend the service life. Fully enclosed dustproof structure, low noise and low energy consumption, easy to maintain.

High Screening Efficiency: Achieves over 95% efficiency.

High Output: Delivers 5-10 times higher output compared to vibrating screens.

Wide Range of Fineness: Efficiently screens materials from 80 to 530 mesh.

Consistent Product Quality: Ensures no over-sized particle mixing.

Durable Design: Vertically installed screen with a long service life.

Dust-Free Operation: Screening process occurs in a negative pressure semi-circulation state, eliminating dust pollution.

Versatile Compatibility: Can be used with various grinders and wind ducts.

Low Noise and Power Consumption: Operates quietly with reduced maintenance needs.

Clog-Free Operation: Airflow as the screening medium prevents common blockage and adhesion issues, enhancing stability and reliability.

Use of Vertical Airflow Screen

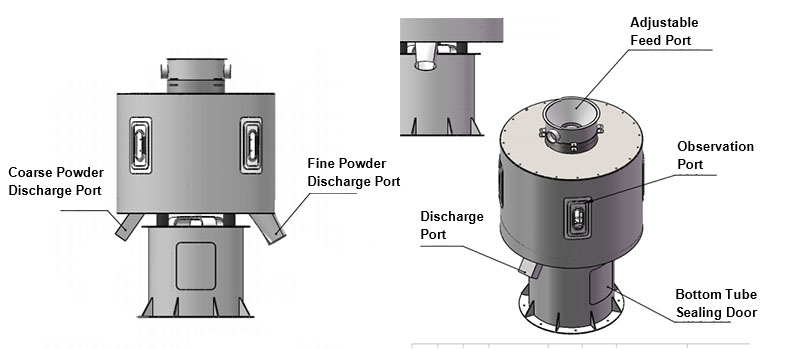

The vertical airflow screen mainly uses airflow to screen materials. The materials screened by this equipment are fine powders. This kind of material is small, thin, easy to float and has good flow performance. After such materials enter the vertical airflow screen, they are impacted by strong airflow and will be separated one by one without agglomeration. In this way, there will be no blockage or static electricity. In addition, the energy of the vibration motor is continuously replenished, and the airflow continues to push the material. In this way, the fine materials will pass through the screen in single particles with the airflow, and finally complete the screening work.

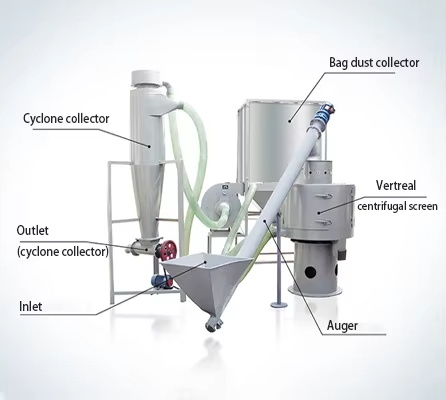

The main machine is an air flow powder screening machine. A vertical cylindrical screen is installed in the closed shell of the screen body. There is a circular wind wheel inside the screen, which is driven to rotate by a motor installed on the base. A feed hopper and a coarse screen are installed just above the screen shell, and a slag discharge port is provided at the bottom. The motor and the main shaft are connected by a belt; the lower opening of the wind wheel hopper forms a feed gap. The gas-solid separation and dust removal device consists of an induced draft fan, a settling chamber and a dust removal bag. The air flow screen and the separation and dust removal device are connected by a plastic corrugated hose.

| Model | LQS600 | LQS-1000 | LQS-1600 |

| Air flow | 240~1100 | 300~2500 | 460~4900 |

| Screen size | 80-600 mesh can be changed at will | ||

| Feed size | 40 mesh or finer | ||

| Screen power | 3 | 5.5 | 15 |

| Spindle speed | 450-1450 | ||

| Screen outer diameter | Φ600 | Φ1000 | Φ1600 |

| Overall height | 1150 | 1730 | 2300 |

The vertical airflow screen is extensively used for screening and grading powdered materials across various industries including chemical, papermaking, metallurgy, building materials, medicine, food, rubber, plastic, machinery, and mining. It is suitable for a wide range of materials such as:

light calcium powder, heavy calcium powder, fly ash, graphite powder, starch, gold powder, zinc powder, clay powder, perlite powder, hawthorn powder, fruit powder, glass powder, pesticide powder, iron powder, Chinese medicine powder, konjac powder, wood powder, flour, etc. According to the fineness requirements of the screened materials, the screen can be replaced arbitrarily within the fineness range of 100 mesh to 500 mesh. The screen material can be stainless steel mesh, copper mesh or nylon mesh.

Thirty years of dedication have allowed us to accumulate extensive production and service experience, enabling us to solve various challenges in powder processing for our numerous clients.

Innovation is the lifeblood of our company's development. To date, we have obtained over 40 domestic and international patents, with many of our products holding multiple patents.

We specialize in undertaking the design and production of fine powder processing production lines, offering a one-stop service from crushing, screening, conveying, feeding, mixing to packaging.

Upon receipt of the products, detailed English user manuals are provided. For relatively complex installations or product usage, video installation guidance is available. For large-scale technical projects, we can dispatch professional technical personnel for on-site installation guidance.

Please fill in the informationWe provide you with personalized solutions

Please fill in the informationWe provide you with personalized solutionsIf you do not know how to select, please call us or leave a message online. We will serve you wholeheartedly!