The rotary vibrating screen is a high-precision screening equipment designed to remove impurities, grade materials, and filter substances. It can efficiently handle dry, wet, fine, rough, large, and small specific gravity powders and particles, with mesh sizes ranging from 0-500. Additionally, it can filter slurry materials with mesh sizes from 0-600. The screen can be configured in single or multiple layers, up to 5 layers, providing flexibility for various screening needs. With low noise and high efficiency, it allows for quick screen changes in just 3-5 minutes. The fully enclosed structure is ideal for screening and filtering particles, powders, and mucus.

High Efficiency: Exquisite and durable design suitable for screening any powder and mucus.

Easy Screen Change: Simple operation and convenient cleaning with quick screen changes in just 3-5 minutes.

No Blockage: The mesh design prevents clogging and powder from flying, enabling screening up to 500 mesh or 0.028mm.

Automatic Discharge: Impurities and coarse materials are automatically discharged, enabling continuous operation.

Unique Mesh Design: Long-term use of the screen with quick and easy screen changes.

Compact Size: Space-saving design that is easy to move.

Multi-layer Screening: Capable of reaching up to five layers, with a recommendation of three layers for optimal performance

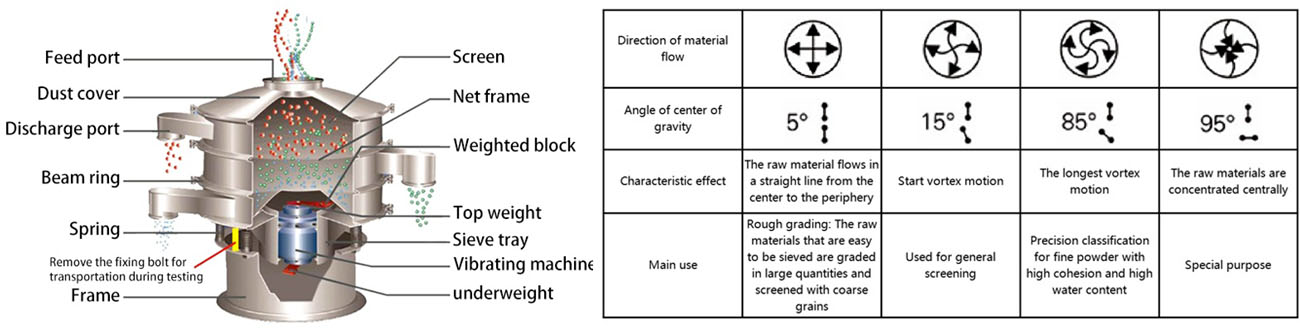

The rotary motion of the motor is transformed into horizontal, vertical, and inclined three-dimensional motion by the weights (unbalanced weights) installed above and below the motor shaft. This motion is then transmitted to the screen surface, causing the material to move outward on the screen. This series of vibrating screens, known as rotary vibrating screens, offers a long material running trajectory and high screen surface utilization. Adjusting the phase angle of the weights at the upper and lower ends changes the material's movement trajectory on the screen surface, allowing for fine screening and probabilistic screening.

| Model | Effective diameter | Screen size | Layer | Power(KW) |

| SY-400 | 380 mm | 2-500 mesh | 1-3 layers | 0.25 kw |

| SY-600 | 580 mm | 1-3 layers | 0.55 kw | |

| SY-800 | 780 mm | 1-4 layers | 0.75 kw | |

| SY-1000 | 970 mm | 1-4 layers | 1.1 kw | |

| SY-1200 | 1170 mm | 1-5 layers | 1.5 kw | |

| SY-1500 | 1470 mm | 1-5 layers | 2.2 kw | |

| SY-1800 | 1770 mm | 1-5 layers | 3 kw |

All kinds of powder industries can screen any particles, powders, and mucus within a certain range.

l Chemical industry: resin powder, pigment, washing powder, paint, soda ash, lemon powder, etc.

l Abrasive, ceramic industry: alumina, quartz sand, mud, spray soil particles.

l Food industry: sugar, salt, alkali, monosodium glutamate, milk powder, soy milk, yeast, juice, etc.

l Papermaking industry: coating, clay mud, black and white liquid, papermaking liquid, wastewater recycling.

l Metallurgical industry: titanium oxide, zinc oxide, electromagnetic materials, metal powder, welding rod powder, etc.

l Pharmaceutical industry: Chinese medicine powder, Chinese medicine liquid, western medicine powder, western medicine liquid, Chinese and western medicine granules, etc.

l Environmental protection: garbage, human and animal feces and urine, waste oil, food wastewater, wastewater processing, etc.

Thirty years of dedication have allowed us to accumulate extensive production and service experience, enabling us to solve various challenges in powder processing for our numerous clients.

Innovation is the lifeblood of our company's development. To date, we have obtained over 40 domestic and international patents, with many of our products holding multiple patents.

We specialize in undertaking the design and production of fine powder processing production lines, offering a one-stop service from crushing, screening, conveying, feeding, mixing to packaging.

Upon receipt of the products, detailed English user manuals are provided. For relatively complex installations or product usage, video installation guidance is available. For large-scale technical projects, we can dispatch professional technical personnel for on-site installation guidance.

Please fill in the informationWe provide you with personalized solutions

Please fill in the informationWe provide you with personalized solutionsIf you do not know how to select, please call us or leave a message online. We will serve you wholeheartedly!