The high-frequency filter vibrating screen is a highly efficient screening device designed to handle solid mixed materials with high-frequency vibration and acceleration, ensuring rapid solid-liquid separation. Ideal for fine-grained, high-viscosity slurries such as ceramics, glazes, coatings, pigments, paints, and various slurries, this high-frequency screen enhances screening efficiency and effectiveness.

High-Frequency Vibration and Acceleration: Ensures efficient screening of fine materials.

Effective Liquid-Solid Separation: Achieves superior processing of liquid-solid mixtures.

Reliable Structure: Robust design with strong excitation force, high screening efficiency, low noise, and easy maintenance.

Discharge Port Design: Circular tube design limits slurry flow range, preventing liquid splashing. The rubber baffle acts as a gate, adjustable according to slurry conditions, extending filtration time and improving accuracy.

Adjustable Open High Bracket: Allows height adjustment for feeding equipment, facilitating cleaning and preventing motor damage from liquid accumulation.

The high-frequency filter vibrating screen utilizes high-speed vibrations to generate intense vibrational force, causing materials to move swiftly across the screen surface. Unlike ordinary vibrating screens, this high-frequency screen employs secondary motors as excitation sources, resulting in vibration intensity that is 2-3 times higher. This enhanced intensity breaks the surface tension of viscous slurries, reducing their residence time on the screen and enabling rapid filtration.

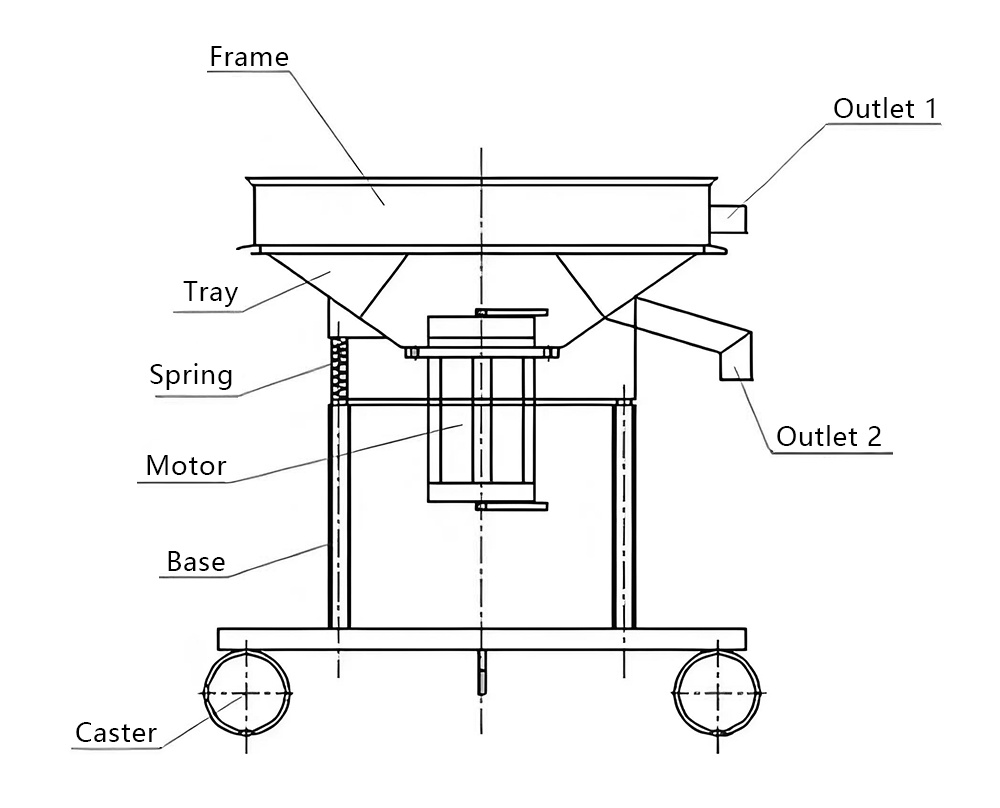

The high-frequency filter vibrating screen is composed of screen frame, frame, spring, screen, vibration motor, tray and other parts. The high-frequency screen uses a 2-stage vibration motor that can rotate 3000 times per minute. It is a type of high vibration frequency and low amplitude. It can quickly separate liquids and solids through the screen. The processing capacity is generally 3 to 5 tons/cubic.

| Model | Power | Diameter | Excitation force |

| SYG-600 | 0.25KW | 560MM | 5000N |

| SYG-800 | 0.55KW | 760MM | 8000N |

| SYG-1000 | 0.75KW | 1000MM | 10000N |

| SYG-1200 | 1.1KW | 1130MM | 15000N |

The high-frequency filter vibrating screen employs a 2-stage high-frequency vibration motor with a 50HZ frequency, a 1-2mm vibration range, a vibration intensity 8-10 times the acceleration, and a high-frequency vibration of 3000 rpm. This ensures that viscous liquids can effectively pass through the screen, making it ideal for screening glazes and other viscous fluids.

l Chemical Industry: Ceramic Slurry, Ceramic Glaze, Paint, Coating

l Food Industry:Juice,Soy Milk, Milk Powder, Protein Powder

l Papermaking Industry: Coating, Clay Slurry, Black and White Liquid, Papermaking Liquid, Wastewater Recycling

l Environmental Protection: Sewage, Food Wastewater, Wastewater Processing

Thirty years of dedication have allowed us to accumulate extensive production and service experience, enabling us to solve various challenges in powder processing for our numerous clients.

Innovation is the lifeblood of our company's development. To date, we have obtained over 40 domestic and international patents, with many of our products holding multiple patents.

We specialize in undertaking the design and production of fine powder processing production lines, offering a one-stop service from crushing, screening, conveying, feeding, mixing to packaging.

Upon receipt of the products, detailed English user manuals are provided. For relatively complex installations or product usage, video installation guidance is available. For large-scale technical projects, we can dispatch professional technical personnel for on-site installation guidance.

Please fill in the informationWe provide you with personalized solutions

Please fill in the informationWe provide you with personalized solutionsIf you do not know how to select, please call us or leave a message online. We will serve you wholeheartedly!