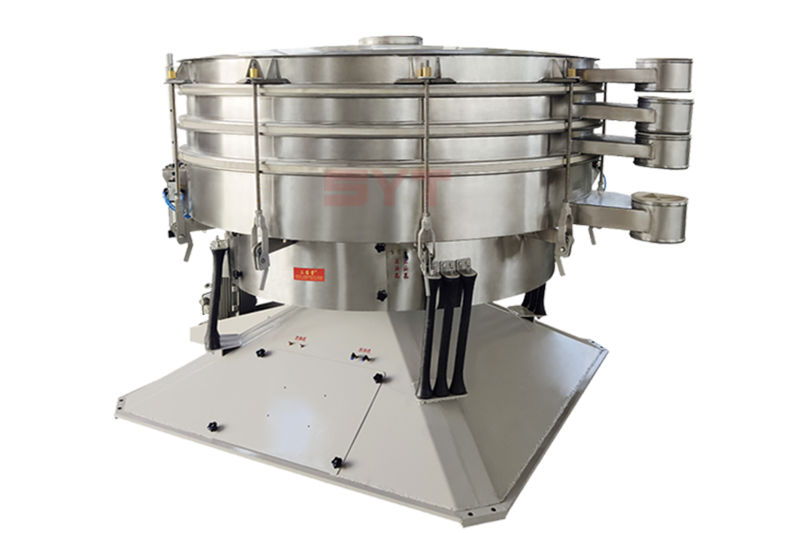

The tumbler screen is a high-efficiency screening machine specifically designed to meet the demands of manufacturers requiring large-scale production and high-precision screening. Mimicking the simplicity of manual screening by hand and eye, the tumbler screen provides the most effective mechanical simulation of this process. It boasts screening accuracy, efficiency, and screen life that are 5-10 times greater than conventional round screens. Ideal for all fine and ultra-fine powders and granular materials, the tumbler screen excels in handling difficult-to-screen materials.

Delivers up to 5 times the output per unit area.Operates quietly with noise levels below 75 decibels.

Achieves precise separation with up to 6 levels of accuracy, boasting a screening efficiency of 90%-99%.

Equipped with advanced cleaning systems, including silicone rubber balls and ultrasonic devices, to prevent screen blockage.

Features an acceleration rate 4-5 times lower than traditional vibrating screens, extending the lifespan of screening parts and reducing maintenance.

Provides enclosed dust removal for safe and clean operation.

Designed with optimized weight balance to ensure a low dynamic load on the foundation.

The tumbler screen operates by mimicking the manual screening process. Its adjustable eccentricity ranges from 25 to 40 mm, and its low-speed V-belt drive can be set between 120 to 360 rpm. The residence time of each product can be modified by adjusting the radial direction and the swing screen's cutting angle towards the drive axis. This setup creates a horizontal and throwing three-dimensional tumbling motion.

Materials are evenly dispersed across the entire screen surface, moving from the center to the outer edge, and then propagate axially in a spiral motion. Fine particles complete the screening process efficiently, while the horizontal and vertical accelerations enhance particle movement. Particles close to the sieve hole size are successfully separated, and larger particles are directed to the outlet, where an adjustable guide device manages flow. This mechanism is essential for controlling material residence time, and the process is consistently repeated across each screen layer for optimal efficiency.

Material Movement Mode

The adjustment of the warp angle and tangential angle can adjust the involute movement on the screen. This movement allows the material to travel a relatively long distance in a smaller area to improve the screening accuracy. The unique design makes the material's netting time longer than other screens, and the screening output is relatively improved.

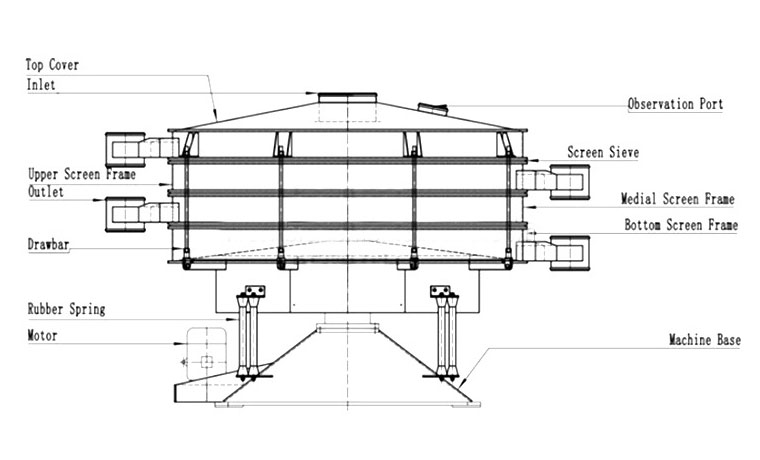

Circular tumbler screens usually consist of a dust cover, feed port, screen, screen, mesh frame, discharge port, and other parts.

Feed port: The design of the buffer plate allows the material to flow evenly into the screen surface, and the material can be inspected through the viewing port.

Dust cover: It limits the material's movement range and protects the machine and the surrounding environment from dust.

Vibration motor: The vibration motor makes the vibrating screen vibrate in multiple planes. This movement increases the speed of the material passing through various sieves.

Shock-absorbing spring: Let the entire upper part of the machine vibrate freely, it helps to minimize power consumption, prevent any vibration from being transmitted to the floor, and reduce noise.

Screen: Maintains tension and makes it easier for the material to move in the direction of vibration. This can be horizontal or vertical. One machine can achieve the separation of multiple materials at the same time.

Discharge port: The discharge port size can be designed according to needs, and the discharge speed through the valve can be adjusted according to needs.

Model | YBS-1000 | YBS-1200 | YBS-1600 | YBS-2000 | YBS-2200 | YBS-2600 |

Diameter (mm) | 1040 | 1250 | 1580 | 1880 | 2100 | 2650 |

Screening Area (㎡) | 0.71 | 1.11 | 1.83 | 2.62 | 3.46 | 5.31 |

| Space Requirements (m³) | 1.2 | 1.6 | 2.5 | 4 | 4.84 | 7 |

| Layers | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 |

| Power(kw) | 1.5 | 2.2 | 2.2/4 | 2.2/4 | 3/4 | 5.5 |

1. Chemical industry: Circular tumbler screen can be used for screening chemical raw materials, grading, and classification of granular materials, such as plastic granules, rubber granules, fertilizers, pigments, resins, etc.

2. Food industry: In food processing, circular tumbler screen is often used for screening and removing impurities from powdered or granular food raw materials, such as flour, starch, powdered sugar, grains, etc.

3. Pharmaceutical industry: Circular tumbler screenn is widely used in granular material screening, powder dispersion, and classification of drug particles in pharmaceutical processes, such as pharmaceutical raw materials, medicinal powder, herbal granules, etc.

4. Mining industry: In ore processing and ore beneficiation, circular tumbler screen is used for screening, grading and separation of granular materials, such as coal, iron ore, copper ore, gold ore, etc.

5. Building materials industry: Circular tumbler screen can be used in the production process of building materials, such as screening, grading and removal of impurities from granular materials such as cement, limestone, sandstone, gypsum, etc.

6. Metallurgical industry: In metallurgical processes, circular tumbler screener can be used for screening of metal powders, alloy particles, slag, etc. and for classification of powders.

7. Plastics industry: Circular tumbler screening machine are widely used in the production process of plastic products for screening, grading and removal of impurities in plastic particles, such as plastic particles, plastic granular materials, etc.

Thirty years of dedication have allowed us to accumulate extensive production and service experience, enabling us to solve various challenges in powder processing for our numerous clients.

Innovation is the lifeblood of our company's development. To date, we have obtained over 40 domestic and international patents, with many of our products holding multiple patents.

We specialize in undertaking the design and production of fine powder processing production lines, offering a one-stop service from crushing, screening, conveying, feeding, mixing to packaging.

Upon receipt of the products, detailed English user manuals are provided. For relatively complex installations or product usage, video installation guidance is available. For large-scale technical projects, we can dispatch professional technical personnel for on-site installation guidance.

Please fill in the informationWe provide you with personalized solutions

Please fill in the informationWe provide you with personalized solutionsIf you do not know how to select, please call us or leave a message online. We will serve you wholeheartedly!