Honey Processing Machine is a processing equipment designed for heat-sensitive materials such as honey. It is mainly used to remove excess water from honey to increase its concentration and extend its shelf life. Through specific processes and technical means, the fine processing of honey is achieved. honey processing machines are widely used in the honey processing industry to increase the concentration of honey and extend its shelf life.

Complete functions, the honey processing machine integrates vacuum suction, dissolution and crystallization, instant filtration and sterilization, rapid cooling, low-temperature concentration, continuous feeding and continuous discharging;

Further sterilize, remove impurities and dissolve crystal nuclei of honey to improve the purity of honey and make the quality better;

The honey processing machine achieves wide adaptability, high efficiency and energy saving, improves work efficiency, and can achieve high quality results;

honey processing machine

It is simple to operate and easy to move.It is equipped with an automatic temperature display, flow hole, sampling hole, water-honey separator, and concentration-indicating adjustable valve, so that the honey processing situation can be observed at any time;

It can prevent and delay the browning of honey, remove impurities, prevent honey from fermenting and becoming sour, and delay crystallization.

using heating technology, such as evaporation concentrators to evaporate the water in honey by heating, or using condensation method to condense water vapor and discharge it to achieve the purpose of concentration. Fully automatic honey processing machines may also use the characteristics of honey's lower boiling point at low temperatures to concentrate at relatively low temperatures to reduce damage to the quality of honey.

When using a honey processing machine, the raw honey is first transported to the equipment. After preheating, evaporation and other steps, the excess water is removed, and the concentrated honey is collected. honey processing machines can also be equipped with auxiliary devices such as impurity removal and sterilization to improve the purity and safety of honey.

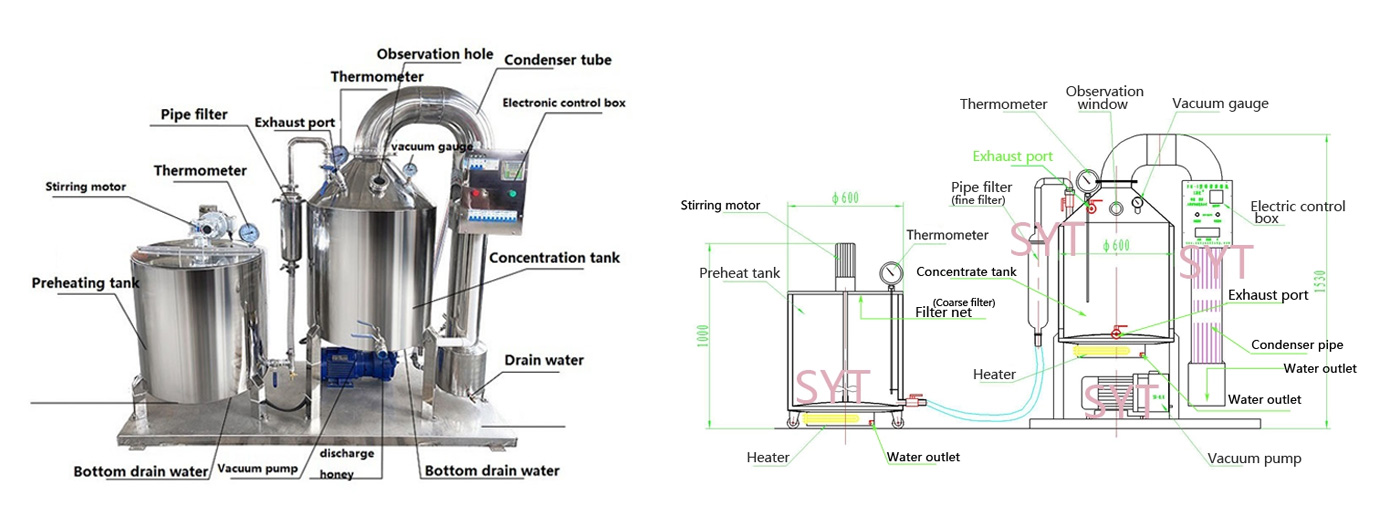

1. The honey processing machine consists of a preheating tank, a filter, a concentrator, a recovery tank, and a vacuum pump. It has a compact structure and occupies a small area. The equipment uses electric heating automatic control for heating, which is easy to use and clean. Install each inlet and outlet valve and connect the material pipe. Generally, the equipment is assembled when it leaves the factory.

2. When the cooling system uses tap water, connect the tap water pipe to the water inlet of the condenser, and the water outlet of the condenser and the water outlet of the vacuum pump are connected to the sewer. The cooling system uses circulating water and must be equipped with a water tank and a water pump. The water storage capacity of the water tank is more than 2 tons, and the water pump power is about 0.37Kw. The water pump pumps the water in the water tank to the water inlet of the condenser, and the water outlets of the condenser and the vacuum pump are connected back to the water tank, and the water in the water tank is used for recycling.

3. Connect the main power cord of the honey processing machine to the distribution box in the workshop, and set the size of the distribution box and the power switch according to the total power. The power supply of the equipment adopts three-phase four-wire system (380V, 50Hz), with a total power of 18Kw. The equipment must also be equipped with a ground wire or a leakage protection switch for the power switch.

Process Flow Of Honey Processing Machine

Raw honey → coarse filtration → stirring, preheating → fine filtration → low-temperature concentration → filling

1. Pre-treatment of purchased honey (i.e. pre-treatment workshop), which mainly melts the purchased honey at low temperature (temperature controlled at 40℃), and uses a filter of about 50 mesh to filter out larvae, pupae, dead bees, and other impurities in the raw honey.

2. Honey processing (i.e. processing workshop), this stage mainly heats, stirs, and finely filters the coarsely filtered honey before entering the concentration equipment. In this process, the temperature, vacuum degree and honey flow rate should be controlled. If high-quality bottled honey is produced, sterilization and melting of crystal nuclei are carried out before entering the concentration process, and another filtration is carried out before packaging after concentration.

3. Packaging workshop, filling machine, capping, sealing, labeling, coding, packaging and other processes are all completed on the workbench conveyor.

| Model | FM-600 | FM-400 |

| Production capacity | 1.2-1.5t/8h | 0.4-0.5t/8h |

| Machine dimension | 1750*600*1660 | 1600*500*1555 |

| Tank diameter | 600mm | 400mm |

| Tank height | 600mm | 600mm |

| The overall volume | 140L | 70L |

| Effective volume | 120L | 60L |

| Preheat tank power | 6KW | |

| Vacuum concentration tank power | 9KW |

In addition to honey, honey processing machines can also be used to concentrate various fruit juices, syrups and other foods.

In the pharmaceutical field, honey processing machines also have broad application prospects. Some drugs need to be concentrated during the production process, and honey processing machines can maintain the active ingredients and efficacy of drugs through their unique low-temperature evaporation technology, ensuring the quality and safety of drugs.

Thirty years of dedication have allowed us to accumulate extensive production and service experience, enabling us to solve various challenges in powder processing for our numerous clients.

Innovation is the lifeblood of our company's development. To date, we have obtained over 40 domestic and international patents, with many of our products holding multiple patents.

We specialize in undertaking the design and production of fine powder processing production lines, offering a one-stop service from crushing, screening, conveying, feeding, mixing to packaging.

Upon receipt of the products, detailed English user manuals are provided. For relatively complex installations or product usage, video installation guidance is available. For large-scale technical projects, we can dispatch professional technical personnel for on-site installation guidance.

Please fill in the informationWe provide you with personalized solutions

Please fill in the informationWe provide you with personalized solutionsIf you do not know how to select, please call us or leave a message online. We will serve you wholeheartedly!