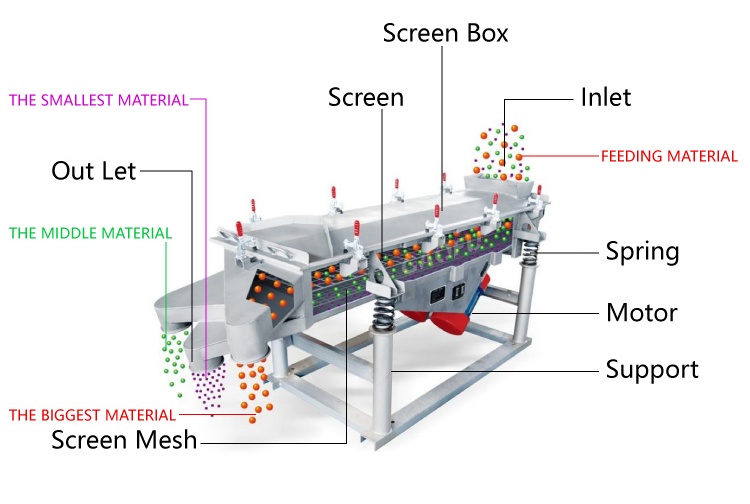

SYZ series linear vibrating screen is mainly composed of screen box, screen frame, screen, vibration motor, motor pedestal, vibration damping spring, bracket, etc.

The linear vibrating screen uses the vibration motor excitation as the vibration source to make the material be thrown up on the screen and move forward linearly at the same time. The material enters the feed port of the screening machine evenly from the feeder, and produces several specifications of screened materials and screened materials through the multi-layer screen, which are discharged from their respective outlets. It has the characteristics of low energy consumption, high output, simple structure, easy maintenance, fully enclosed structure, no dust overflow, automatic discharge, and is more suitable for assembly line operation

Efficient screening: The linear screen uses a vibration motor to generate linear vibration, so that the material moves quickly on the screen, achieving efficient screening and improving production efficiency.

Accurate grading: By adjusting the amplitude and vibration frequency of the vibration motor, accurate grading of materials can be achieved to meet the screening requirements of different particle sizes.

Simple structure: The linear screen has a relatively simple structure, usually consisting of a vibration motor, a screen box, a screen and a base, which is easy to install and simple to maintain.

Wide application: Linear screen is suitable for screening a variety of granular materials, including ore, coal, building materials, chemical raw materials, food, etc., and has a wide range of applications.

High reliability: The linear screen is made of high-quality materials, has stable and reliable performance, and is not prone to failure after long-term use.

Low noise: The linear screen has low noise during operation and will not interfere with the working environment and operators.

Environmental protection and energy saving: The linear screen is driven by a vibration motor. Compared with traditional screening equipment, it has lower energy consumption and is conducive to energy conservation and emission reduction.

Convenient adjustment: The screening speed and screening effect of the material can be controlled by adjusting the amplitude and vibration frequency of the vibration motor to meet the screening needs of different materials.

1. Vibration motor drive: The linear screen is driven by the vibration motor. The vibration motor generates excitation force through the exciter to make the screen box move linearly.

2. Material input: The material to be screened is put into the screen box through the feed port.

3. Screening process: Under the action of vibration, the material in the screen box is affected by centrifugal force and inertia force, and moves linearly on the screen. Smaller particles will pass through the pores of the screen, while larger particles will be blocked on the surface of the screen.

4. Separate materials: During the screening process, materials that meet the requirements will fall through the screen into the aggregate box or conveyor belt below, while materials that do not meet the requirements will be retained on the screen.

5.Adjust vibration parameters: The screening speed and screening effect of the material can be controlled by adjusting the amplitude and vibration frequency of the vibration motor to meet the screening requirements of different materials.

1.The linear vibrating screen is mainly composed of a screen box, a screen mesh, a vibrator, a vibration-damping spring, and a supporting device.

2.The screen box is the main part of the linear vibrating screen, usually welded from steel plates, and has sufficient strength and rigidity.

The screen box is equipped with multiple layers of screen mesh, and the material and aperture of the screen mesh can be selected according to the requirements of the material.

3.The vibrator is the core component of the linear vibrating screen, usually a double eccentric shaft vibrator or a vibration motor.

The vibrator causes the screen box to vibrate linearly through the excitation force, thereby achieving material screening.

4.The vibration-damping spring is installed between the vibrator and the screen box to play a role in vibration reduction and support.

The supporting device usually uses a wire rope or a steel leaf spring to keep the screen box in horizontal motion.

| Model | SYZ-520 | SYZ-840 | SYZ-1030 | SYZ-1255 | SYZ-1650 |

| Dimension(mm) | 500*2000 | 800*4000 | 1000*3000 | 1200*5500 | 1600*5000 |

| Granularity(mm) | 0.074-60 | 0.074-60 | 0.074-60 | 0.074-60 | 0.074-60 |

| Speed(r/min) | 960 | 960 | 960 | 960 | 960 |

| Amplitude | 4-8 | 4-8 | 4-8 | 4-8 | 4-8 |

| Deck | 1-4 | 1-4 | 1-4 | 1-4 | 1-4 |

| Power(kw) | 2×0.75 | 2×1.5 | 2×1.9 | 2×2.2 | 2×3.0 |

As a common screening equipment, linear screens are widely used in many industries, mainly including the following aspects:

1. Mining and metallurgical industry: used for screening and grading raw materials such as ore, coal, metal ore, non-metallic ore, such as screening ore in a beneficiation plant to separate ores of different particle sizes to meet the needs of smelting and processing.

2. Building materials industry: used for screening and grading building materials such as sandstone, limestone, cement, etc., such as screening aggregates in concrete production to control the proportion of concrete ingredients.

3. Chemical industry: used for screening and grading of chemical raw materials and granular materials, such as screening raw materials in the production process of granular materials to ensure product quality.

4. Food industry: used for screening and grading of food raw materials and food additives, such as screening powdered raw materials in food processing to remove impurities and improve product quality.

5. Pharmaceutical and bioengineering industry: used for screening and grading of pharmaceutical raw materials and biological products, such as screening medicinal materials in pharmaceutical factories to separate medicinal materials that meet the requirements.

6. Environmental protection and waste treatment industry: used in environmental protection fields such as waste treatment and recycling, such as screening waste in garbage treatment plants to separate recyclable materials.

Thirty years of dedication have allowed us to accumulate extensive production and service experience, enabling us to solve various challenges in powder processing for our numerous clients.

Innovation is the lifeblood of our company's development. To date, we have obtained over 40 domestic and international patents, with many of our products holding multiple patents.

We specialize in undertaking the design and production of fine powder processing production lines, offering a one-stop service from crushing, screening, conveying, feeding, mixing to packaging.

Upon receipt of the products, detailed English user manuals are provided. For relatively complex installations or product usage, video installation guidance is available. For large-scale technical projects, we can dispatch professional technical personnel for on-site installation guidance.

Please fill in the informationWe provide you with personalized solutions

Please fill in the informationWe provide you with personalized solutionsIf you do not know how to select, please call us or leave a message online. We will serve you wholeheartedly!