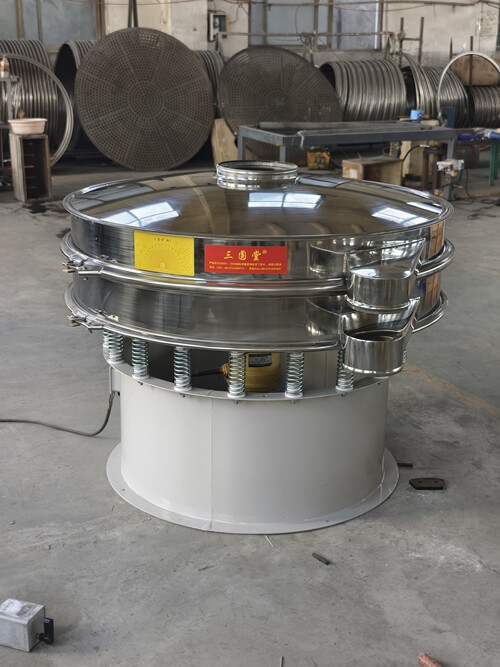

Food products come in many different forms, generally classified as powders, granules, and liquids. During food processing or final packaging, screening and filtration are often required to ensure smooth processing and enhance product quality and taste. Sanyuantang Machinery specializes in manufacturing high-quality food-grade rotary vibrating screens, specifically designed for fine screening and impurity removal during powder processing.

For powdered food materials, rotary vibrating screens (also known as circular vibrating screens) are the preferred choice. These machines can achieve ultra-fine screening accuracies up to 500 mesh (25 microns), meeting the stringent standards of modern food production.

To ensure food safety, all product-contacting parts are made of stainless steel (304 or 316L) and polished to a mirror-smooth finish. The seamless surface prevents powder buildup, makes the screen easy to clean, and prevents contamination or mold growth.

The rotary vibrating screen uses a vertical vibration motor as the excitation source. The motor’s upper and lower eccentric weights generate a three-dimensional motion—horizontal, vertical, and inclined—causing the material on the screen surface to move in a spiral pattern.

This unique motion allows the material to be efficiently separated through different mesh layers, achieving precise grading, impurity removal, or solid-liquid separation.

For food powders, this ensures fast throughput, accurate separation, and minimal material loss while maintaining product integrity.

High Screening Precision

With mesh sizes up to 500 mesh, it easily handles precise grading and impurity removal for nearly all types of food powders.

Food-Grade Sealing System

Equipped with an FDA-approved silicone seal, it ensures a complete seal, preventing material leakage and waste during screening.

Automatic Screen Cleaning System

Food-grade silicone screen cleaning balls ensure rapid screen clearance and promptly remove any food powder adhering to the screen.

Flexible Connection and Discharge Design

It can be equipped with a top cover and flange inlet for connection to crushing equipment or feeding equipment. The 360-degree rotatable discharge port allows for adjustment to suit your production site.

| Model | Effective diameter | Screen size | Layer | Power(KW) |

| SY-400 | 380 mm | 2-500 mesh | 1-3 layers | 0.25 kw |

| SY-600 | 580 mm | 1-3 layers | 0.55 kw | |

| SY-800 | 780mm | 1-4 layers | 0.75kw | |

| SY-1000 | 970mm | 1-4 layers | 1.1kw | |

| SY-1200 | 1170mm | 1-5 layers | 1.5kw | |

| SY-1500 | 1470mm | 1-5 layers | 2.2kw | |

| SY-1800 | 1770mm | 1-5 layers | 3kw |

Sanyuantang machine food-grade vibrating screens are widely used in:

Flour and starch (e.g., wheat, tapioca, and potato starch)

Coffee and cocoa powders

Spices and seasoning powders

Protein and milk powders

Additives and food ingredients

Whether grading, removing impurities, or screening for safety before packaging, Sanyuantang vibrating screens provide a one-stop screening solution.

Sanyuantang Machinery has over 10 years of international trade experience, serving customers in hundreds of countries. The food, pharmaceutical, and chemical industries trust our screening equipment.

Sanyuantang Machine consistently provides customized solutions for its customers, ensuring that every batch meets the highest quality standards.

Looking for a hygienic and efficient screening system for your food powder production line?