The dust-free feeding station is suitable for the unpacking, feeding, screening, and unloading of small bags of materials in the pharmaceutical, chemical, food, battery materials, and other industries. When unpacking, due to the function of the dust-collecting fan, the material dust can be prevented from flying everywhere.When the materials are unpacked and poured into the next process, they only need to be manually unpacked and put into the system directly. The materials pass through the vibrating screen safety screen) to intercept the bulk materials and foreign objects, so as to ensure that the particles that meet the requirements are discharged.

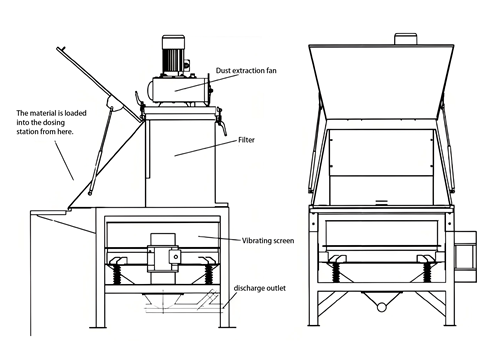

The dust-free feeding station is composed of a feeding platform, an unloading bin, a dust removal system, a vibrating screen, and other components.

Negative Pressure Dust Collection System: Utilizes a built-in fan to generate negative pressure, drawing dust generated during material feeding into a filtration system. This prevents dust overflow, reduces material waste, and minimizes environmental pollution.

Intelligent Filtration & Cleaning: Equipped with high-efficiency filters and pulse-jet cleaning technology, the system automatically cleans filter screens at regular intervals to prevent clogging and extend service life.

Material & Dimension Adaptability: Main structure supports stainless steel (304/316L), carbon steel, and other materials. Overall height, hopper capacity, and design can be non-standard customized to fit site layouts.

Multi-Industry Applications: Suitable for pharmaceutical, chemical, food, mining, and other sectors. Handles powders, granules, and small-block materials (e.g., refining agents, battery materials, food additives).

System Integration Capability: Operates independently or connects to central dust collection pipelines/downstream equipment, enhancing production line continuity.

The working principle of the vacuum feeder is based on negative-pressure pneumatic conveying technology. The compressed air forms negative pressure in the hopper to attract and promote the efficient flow of materials in the sealed pipeline. It is also supplemented by intelligent material-level control to ensure accurate and dust-free delivery of materials. Transported to the designated location, the automation and cleanliness of material transport are realized.

Feeding platform: For manual placement and bag opening.

Dust collection system: Includes high-efficiency filter, fan, and pulse jet cleaning system.

Hoop and discharge port: Materials are collected and fed into downstream equipment such as screw conveyors, vibrating screens, and mixers.

Frame and outer casing: Constructed of SUS304 stainless steel, robust, durable, and easy to clean.

Optional configurations: Vibrating screening system, magnetic rods, weighing system, etc.

Model | Dust collection fan | Vibration motor | Dust filter |

HC-800 | 1.1KW | 0.18KW | 0.4um(Coated polyester filter cartridge) |

HC-1000 | 1.5KW | 0.18KW | 0.4um(Coated polyester filter cartridge) |

The dust-free feeding station is suitable for feeding processes of various powder and granular materials.

Food processing industry: Milk powder, wheat flour, icing sugar, cocoa powder, seasonings, food additives, etc.

Chemical industry: Pigments, dyes, carbon black, graphite powder, flame retardants, plastic powder, etc.

Pharmaceutical Industry: APIs, TCM powders, chemical drug powders, excipients (e.g., lactose, starch), vitamin powders, etc.

New Energy Industry: Lithium-ion battery cathode and anode materials (e.g., lithium cobalt oxide, lithium iron phosphate), carbon powder, etc.

Thirty years of dedication have allowed us to accumulate extensive production and service experience, enabling us to solve various challenges in powder processing for our numerous clients.

Innovation is the lifeblood of our company's development. To date, we have obtained over 40 domestic and international patents, with many of our products holding multiple patents.

We specialize in undertaking the design and production of fine powder processing production lines, offering a one-stop service from crushing, screening, conveying, feeding, mixing to packaging.

Upon receipt of the products, detailed English user manuals are provided. For relatively complex installations or product usage, video installation guidance is available. For large-scale technical projects, we can dispatch professional technical personnel for on-site installation guidance.

Please fill in the informationWe provide you with personalized solutions

Please fill in the informationWe provide you with personalized solutionsIf you do not know how to select, please call us or leave a message online. We will serve you wholeheartedly!