1. Functional focus on "pretreatment + mixing," resulting in a compact process.

2. Specifications suitable for small and medium-sized production capacity, offering high flexibility.

3. Mixing technology focuses on "uniformity," adaptable to specific materials.

In modern food processing, especially in flour-based production lines, ensuring material cleanliness, fineness uniformity, and consistency of blending is key to delivering high-quality end products. To address the industry’s needs, we have developed a complete flour sieving and mixing production line, which integrates dust-free feeding station, rotary vibrating screen, vacuum feeder, and ribbon mixer.

This system is designed for efficient and hygienic handling of powdered materials like wheat flour, corn flour, rice flour, starches, and pre-mixed baking ingredients—offering stable performance, easy operation, and full compliance with food-grade standards.

✅ High-Precision Screening

Utilizing a multi-layer vibrating screen structure, the system can screen fine powders up to 80 mesh or larger, effectively removing impurities and large particles.

✅ Compact Structure and Small Footprint

The modular design of the production line allows for flexible layout and adaptability to varying factory space requirements.

✅ Safe and Hygienic Materials

All material contact parts are constructed of 304 stainless steel, meeting food-grade hygiene standards and ensuring easy cleaning and maintenance.

✅ Customization Available

We provide customized solutions tailored to your material characteristics, processing capacity, and site conditions.

Thirty years of dedication have allowed us to accumulate extensive production and service experience, enabling us to solve various challenges in powder processing for our numerous clients.

Innovation is the lifeblood of our company's development. To date, we have obtained over 40 domestic and international patents, with many of our products holding multiple patents.

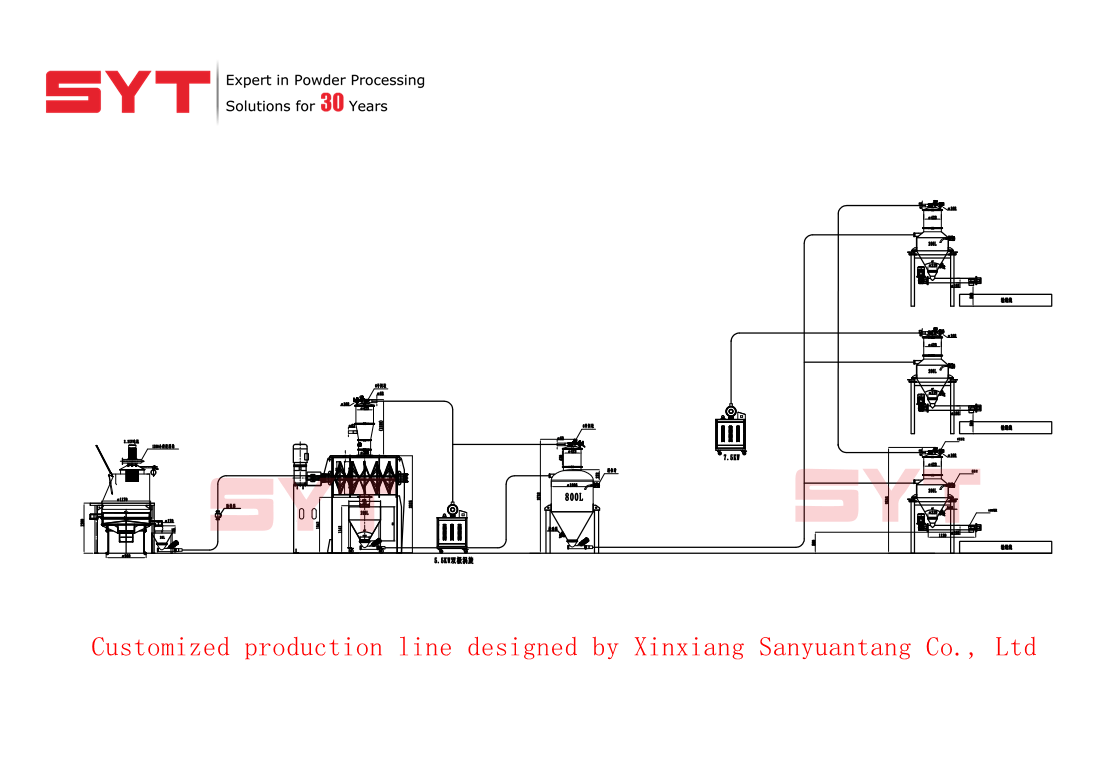

We specialize in undertaking the design and production of fine powder processing production lines, offering a one-stop service from crushing, screening, conveying, feeding, mixing to packaging.

Upon receipt of the products, detailed English user manuals are provided. For relatively complex installations or product usage, video installation guidance is available. For large-scale technical projects, we can dispatch professional technical personnel for on-site installation guidance.

Please fill in the informationWe provide you with personalized solutions

Please fill in the informationWe provide you with personalized solutionsIf you do not know how to select, please call us or leave a message online. We will serve you wholeheartedly!