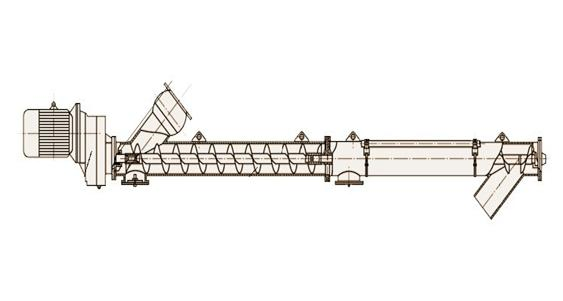

Shaftless screw conveyors revolutionized bulk material handling by eliminating central shafts, using flexible spiral flights to transport challenging materials. Industries like wastewater treatment, food processing, and chemical manufacturing rely on their superior anti-clogging performance. But with diverse models available, how do you select the optimal shaftless conveyor system? This comprehensive guide breaks down the 5 critical selection factors.

Your hourly material throughput dictates the conveyor’s size. Undersized units cause bottlenecks; oversized systems waste energy and budget.

Low-Capacity Applications (<20 m³/hr): Choose 200–300mm diameter shafts for sludge or light waste.

High-Volume Needs (50–100+ m³/hr): Opt for 400–600mm models in cement or grain processing.

Pro Tip: Calculate peak output + 15% buffer for future scalability.

Speed impacts productivity and product quality. High velocity risk:

Material Damage (e.g., fractured pellets)

Vibration/Noise in belt-driven systems

Increased Wear on spiral flights

Optimal Ranges:

| Material Type | Recommended Speed |

|------------------------|-------------------|

| Sludge/Sticky Waste | 10–20 RPM |

| Grains/Powders | 25–45 RPM |

| Aggregates/Mining Ore | 15–30 RPM |

Key Insight: Variable Frequency Drives (VFDs) allow real-time speed adjustments.

Critical measurements directly impact performance:

Flight Diameter (200–600mm): Dictates volume capacity.

Trough/Pipe Size: Prevents material jamming (e.g., 10–15% larger than max particle size).

Hopper Volume: Ensures consistent feed without overflow.

Example: For food waste (containing 50mm solids), select a 350mm pipe + 420mm flight.

Length and angle exponentially affect power needs:

Horizontal Systems (<30m): Standard motors suffice.

Inclined Conveyors (15°–30°): Requires 20–40% more torque.

Vertical/Long-Run (>40m): Needs reinforced flights + heavy-duty motors.

Note: Every 10° incline reduces efficiency by 12% – consult engineering specifications.

Motors make or break your system:

Standard Motors: Cost-effective for fixed-speed operations.

VFD-Enabled Motors: Essential for speed-sensitive materials (e.g., recycling plants).

Torque Ratings: Calculate based on material density (e.g., sewage sludge = 1,200 kg/m³).

Critical: Over-torque protection prevents spiral flight damage.

Bonus: Industry-Specific Selection Tips

Wastewater Plants: Choose corrosion-resistant SS304/316 steel + sealed motors.

Food Processing: FDA-compliant flights with smooth finishes.

Aggressive Materials (e.g., ash): Hard-coated flights + abrasion-resistant liners.

Why Shaftless > Shafted Conveyors?

(Keywords: No-Center-Shaft Benefits, Reduced Maintenance Conveyor)

Zero Jamming: No central shaft for debris wrap.

30% Lower Maintenance: Fewer bearings/seals to replace.

Higher Fill Rates: 45–70% vs. 15–30% in shafted models.

Final Checklist Before Purchasing:

Test material density & particle size analysis.

Map conveyor path (horizontal/vertical/inclined).

Specify environmental conditions (temperature, moisture, corrosives).

Compare motor types: IE3 vs. IE4 efficiency classes.

Request CAD layouts for facility integration.

Sanyuantang machine engineers high-capacity shaftless screw conveyors for cement, biomass, sludge, and more.

Get a free design consultation →sales@sanyuantang.com/+8616638408032