Aluminum, the third most abundant metal in the earth's crust, is strong, non-toxic, non-magnetic and lightweight. Bauxite, the raw material for aluminum refining, is mainly composed of 40% to 60% aluminum oxide, as well as sand, iron and other metallic impurities.

Aluminum is used in a wide range of applications, from aluminum foil to aircraft parts, from food cans to building window frames. To gain an advantage in the market, manufacturers pursue high-quality products, which can be achieved by improving product purity and removing impurities. Next, we will explore how to ensure excellent product quality through optimized screening solutions.

Aluminum powder is produced in various forms, including flakes, granules and powders. When aluminum ingots or trays arrive at the factory, they are melted in a furnace at 720 to 760 degrees Celsius and then converted into different grades of aluminum powder through a spray atomizer.

Screening plays a central role in the aluminum powder processing process because it determines the uniformity of the aluminum powder particles, which in turn affects the quality of the final product. Manufacturers often face challenges such as insufficient throughput when using traditional vibrating screens.

Key factors affecting the screening effect include physical properties such as bulk density, humidity, temperature and viscosity of the material. Therefore, it is crucial to choose the right vibration mode, screen plate, material flow medium and tilt angle to ensure the desired screening effect and throughput.

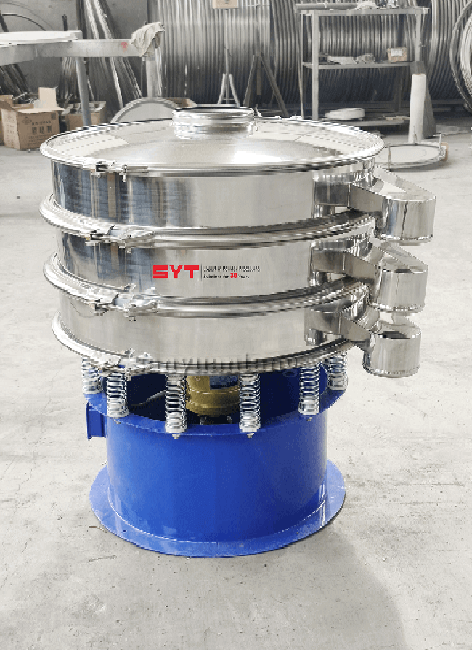

The multi-layer vibrating screen provided by Sanyuantang Machinery is specially designed for aluminum powder grading. It can accurately grade aluminum powder from coarse powder to fine powder, ensuring that each grade of material is pure and uniform without impurities introduced during the processing. These graded aluminum powders will be packaged and supplied to different manufacturers for the production of various aluminum products.

Accurate grading: Multi-layer vibrating screening technology ensures accurate grading of aluminum powder.

Durable material: Made of high-grade stainless steel to extend the service life of the screening equipment.

Efficient throughput: Designed to increase throughput, saving you time and energy.

Easy maintenance: The equipment is easy to assemble and disassemble, reducing maintenance costs and time.

High-quality screening effect: Efficient screening of materials, providing the best screening effect.

Sanyuantang Machinery is committed to creating a powerful screening system for your industry, providing lifelong support and excellent performance. We also provide after-sales service and 24-hour support. Contact us today to solve your screening and filtration challenges.