Explore the functionality, types, and benefits of circular vibrating screens, including round vibrating screens, and circular vibratory screens, and their role in various industries. Learn about the direction of rotation, types of vibrating screens, and where to find circular vibrating screens for sale.

In the field of industrial screening and separation, circular vibrating screens play an important role in ensuring that materials are processed efficiently and accurately. These screens, also known as round vibrating screens, circular vibratory screens, circular vibro screens, circular vibratory screeners, or circular vibrating sieves, are designed to separate particles based on their size, shape, or density. Today, we delve into the intricacies of what a circular vibrating screen does, its various types, and the importance of factors like the direction of rotation and pricing.

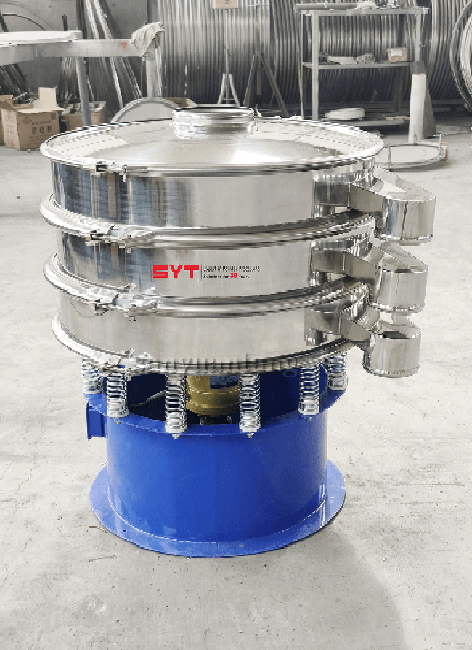

A circular vibrating screen utilizes a circular motion to separate materials into different fractions. The screen deck is mounted on a frame that is vibrated by an eccentric shaft or unbalanced motor, creating a circular motion that propels the material across the screen surface. This motion allows particles to pass through the screen mesh based on their size, while larger particles are retained on top for further processing or disposal.

Circular Motion Vibrating Screen: The most common type, it utilizes a circular motion to effectively screen a wide range of materials from fine powders to coarse aggregates.

Direct discharging vibrating screen: These are often customized to suit specific industrial requirements and can be purchased in various sizes and capacities.

Rotary Vibro Screens: Specially designed for delicate materials or those requiring high-precision screening, vibro screens minimize damage during the separation process.

Tumble Vibratory Screeners: Used in applications where continuous screening is necessary, they offer high throughput and reliability.

High Efficiency: The circular motion ensures even distribution of material across the screen, maximizing screening efficiency.

Versatility: Suitable for a wide range of materials, including wet and sticky materials, and can be tailored to specific screening requirements.

Easy Maintenance: Modular design makes maintenance and cleaning straightforward, reducing downtime.

Adjustable Motion: The direction of rotation and amplitude can be adjusted to optimize screening performance for different materials.

The direction of rotation, whether clockwise or counterclockwise, can significantly impact screening efficiency. The choice depends on the material's characteristics and the desired screening outcome. In some cases, reversing the direction of rotation can help dislodge stuck particles, enhancing screening effectiveness.

Vibrating screen prices vary based on factors such as size, capacity, material of construction, and customization options. While some manufacturers offer standard models, others specialize in custom-built solutions to meet unique industrial needs. Circular vibrating screens for sale can be found through various suppliers, both online and offline, with pricing ranging from affordable to premium depending on the specific requirements.

Circular vibrating screens are indispensable in various industries, from mining and aggregates to food processing and chemicals. Their versatility, efficiency, and ease of maintenance make them a preferred choice for material separation. Understanding the different types, their key features, and the impact of factors like the direction of rotation can help businesses select the optimal screening solution for their specific needs. When shopping for circular vibrating screens, consider the material being screened, production requirements, and budget to make an informed decision.