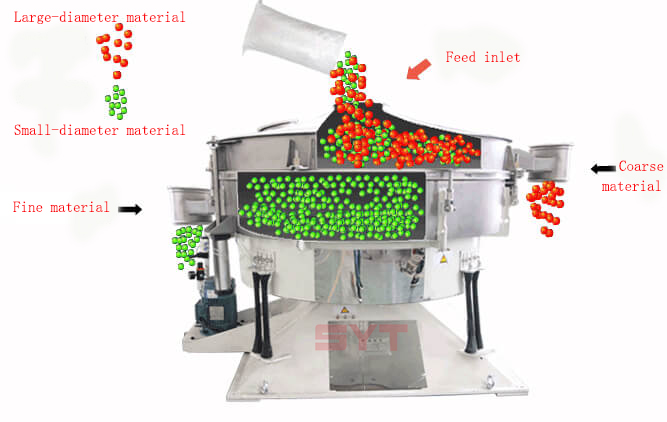

The tumbler screen, also known as a circular tumbler sieve, adopts a simulated manual sieving principle. It delivers high precision and efficiency for separating powders and granules into 1–6 grades. This machine is particularly suitable for fine, light, and difficult-to-screen materials.

So, what are the main differences between a tumbler screen and a rotary vibrating screen? Let’s explore them in detail below.

Tumbler Screen: The tumbler screen simulates a manual sieving motion. The screen surface performs a combination of reciprocating, swinging, and rotating movements, allowing materials to move outward slowly in a spiral pattern. This gentle motion ensures precision screening without damaging delicate particles.

Rotary Vibrating Screen: The rotary vibrating screen uses an eccentric block motor to generate three-dimensional vibration (horizontal, vertical, and inclined). This causes materials to jump and disperse rapidly on the screen surface, making it ideal for general-purpose screening and filtering.

The choice between these two screens largely depends on your material characteristics and production goals.

Tumbler Screen:

Suitable for fine powders, light materials, fragile or high-precision products, especially those prone to mesh clogging.

Examples include: pharmaceutical powders, metal powders, quartz sand, silicon carbide, food additives, pearl powder, and plastic micro-particles.

Rotary Vibrating Screen:

Best for general powders and granules where precision requirements are moderate.

Examples include: flour, milk powder, grain powder, resin, chemical granules, and general metal powders.

Note: Rotary vibrating screens use high-frequency vibration, which can sometimes break fragile or crystalline materials such as MSG, seasoning granules, or sugar. The tumbler screen, with its soft elliptical motion, avoids this problem entirely.

When screening materials around 30 mesh, both machines perform similarly.

However, for fine powders up to 500 mesh, the tumbler screen offers significantly higher efficiency and precision.

Tumbler Screen:

Screening precision: up to 95%–99%

Processing capacity: 2–5 times higher than rotary vibrating screens (for the same diameter)

Especially effective for abrasive or hard materials

Rotary Vibrating Screen:

Good for basic classification, impurity removal, and filtering

Suitable for medium or coarse particle screening

Rotary Vibrating Screen:

High-frequency vibration may cause structural fatigue, cracking, or mesh damage over time. It requires more frequent maintenance and parts replacement.

Tumbler Screen:

Operates with low power, low noise, and minimal vibration, which greatly extends the equipment’s service life.

Its stable operation reduces mechanical stress on both the frame and mesh, ensuring long-term reliability.

If your production requires high precision, high yield, and material integrity, the tumbler screen is the ideal choice.

For standard sieving, filtering, or impurity removal tasks, a rotary vibrating screen remains a cost-effective solution.

When choosing a screening machine, always consider your material characteristics, mesh size, and processing capacity. At Sanyuantang Machinery, we can help you select the most suitable model to achieve optimal screening performance for your specific application.

Email:sales@sanyuantang.com