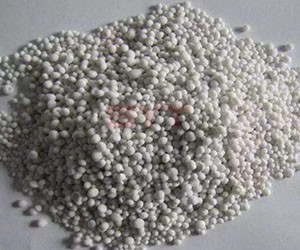

The screening process for fertiliser production consists of pouring the fertiliser into a screening vessel unit, conducting an initial crushing of the fertiliser through a crushing device inside the screening vessel, then falling into the screening unit for screening. During the screening process, the spacing of the screening screen in the screening device shall not exceed 5%, to ensure uniform particle size. If the fertilizer particles are large after screening, will remain in the screening device, and through the crushing roller for secondary crushing, to ensure that the fertilizer is fully screened, to avoid waste.

Thirty years of dedication have allowed us to accumulate extensive production and service experience, enabling us to solve various challenges in powder processing for our numerous clients.

Innovation is the lifeblood of our company's development. To date, we have obtained over 40 domestic and international patents, with many of our products holding multiple patents.

We specialize in undertaking the design and production of fine powder processing production lines, offering a one-stop service from crushing, screening, conveying, feeding, mixing to packaging.

Upon receipt of the products, detailed English user manuals are provided. For relatively complex installations or product usage, video installation guidance is available. For large-scale technical projects, we can dispatch professional technical personnel for on-site installation guidance.

Please fill in the informationWe provide you with personalized solutions

Please fill in the informationWe provide you with personalized solutionsIf you do not know how to select, please call us or leave a message online. We will serve you wholeheartedly!